Cement boards are durable, long lasting building materials used where water, heat, or heavy wear is a problem. Builders rely on them for bathrooms, kitchens and outdoor areas because they are far more impervious than drywall.

These boards are made of cement and are reinforced with fibers that make them incredibly strong for tile, stucco, and other finishes. They are built to work in the harsh environments that break most other materials.

What Exactly Are Cement Boards?

Think of a cement board as a flat sheet that is much tougher than drywall but lighter than poured concrete. Cement boards are made from Portland cement, sand or other aggregates, and reinforcing fibers like cellulose or fiberglass.

Most sheets come in standard 4-foot by 8-foot sizes. Thickness varies based on use:

- 1/4 inch for backsplashes and wall tile

- 1/2 inch or more for floors and walls

- Heavy-duty structural panels can be as thick as 1-9/16 inches

Unlike drywall, cement boards do not swell, break down or soften when they get wet. Some contain additional polymers for increased flexibility. They are great boards for indoor and outdoor applications in humid environments.

Exploring Types of Cement Boards

Cement boards are available in different types, each designed for specific jobs.

Cement-bonded particle boards use treated wood chips mixed with cement. These boards are very strong and are often used for floors or load-bearing walls where strength matters.

Fiber cement boards replace wood with plant-based cellulose fibers. They are lighter, resist mold well, and are commonly used behind tile in bathrooms and for exterior walls.

Specialized options include wood wool cement boards for sound control, insulated panels for energy efficiency, and refractory boards designed to handle very high heat in industrial settings.

| Type | Key Reinforcement | Best For | Load Capacity |

| Cement-Bonded Particle | Wood flakes | Floors, high-load walls | High |

| Fiber Cement | Cellulose fibers | Tile backers, exteriors | Medium |

| Wood Wool Cement | Wood wool | Ceilings, acoustics | Low |

| Refractory | High-heat fibers | Industrial, fireplaces | Varies |

Choose the board based on your needs. Fiber cement works best in wet areas, while particle boards are better for strength and weight support.

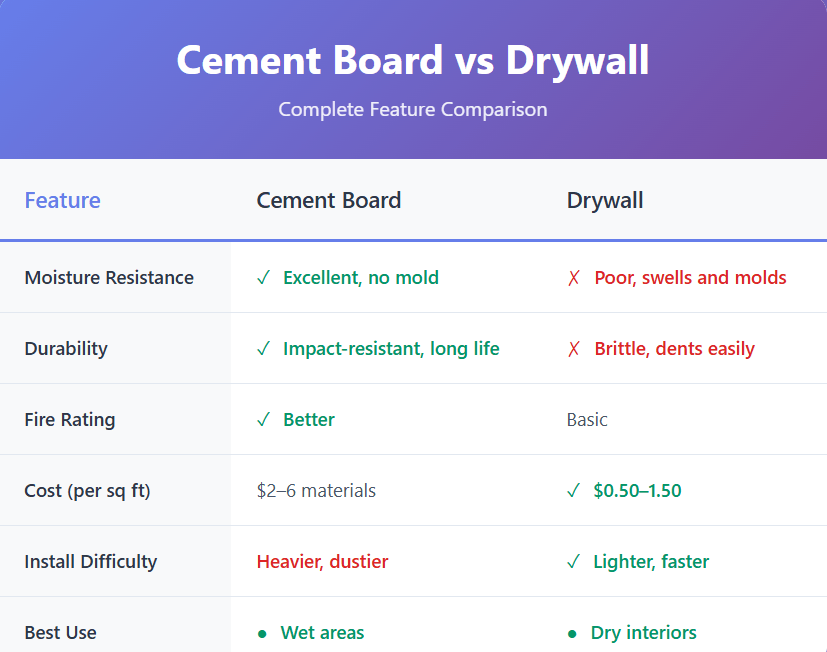

Why Cement Boards Beat Drywall in Tough Spots

Drywall breaks down quickly when exposed to water. Cement boards do not.

They resist mold, handle daily impacts, and offer better fire resistance. That’s why they are commonly used in bathrooms, kitchens, and commercial buildings.

In humid areas, cement boards perform especially well where steam and moisture are constant. They are also pest-resistant, meaning termites and insects won’t damage them. With proper installation, cement boards can last 50 years or more.

Top Applications for Cement Boards

Cement boards are used wherever moisture resistance and durability are important.

They are commonly installed in:

- Shower walls and tub surrounds

- Kitchen backsplashes and countertops

- Exterior walls under stucco or siding

- Flooring under tile in high-traffic areas

- Fireplace surrounds and heat zones

- Interior partitions and false ceilings

Builders rely on cement boards in both homes and commercial spaces where long-term performance matters.

Step-by-Step Cement Board Installation

Basic tools include a utility knife, drill, corrosion-resistant screws, alkali-resistant mesh tape, and thinset mortar.

Start by making sure framing is straight, dry, and clean.

Score and snap boards for straight cuts, and use hole saws for pipes and fixtures. Install full sheets first, leaving a 1/4-inch gap at edges and floor lines for movement. Fasten boards every 8 inches, keeping screws flush and away from edges.

Tape joints with mesh tape and cover them with thinset. Apply two coats of a waterproofing membrane for wet areas. For floors, stagger joints to improve strength.

Always wear a mask when cutting—cement dust contains silica.

Cement Board vs. Drywall: Head-to-Head

Drywall is cheaper and easier to install, but cement boards are better where durability is needed.

Use cement board in bathrooms and kitchens. Drywall is fine for bedrooms and living rooms.

Pros, Cons, and Real-World Fixes

Cement boards offer excellent durability, moisture resistance, and pest protection. They provide a solid base for tile and perform well in humid environments.

However, they are heavy, create dust when cut, and cost more upfront. If not properly sealed, moisture can still penetrate over time. Cracks are generally the result of improper joint taping, and debris on the surface often calls for cleaning followed by resealing.

Maintenance is simple: Clean occasionally in a while, check for damage and repaint exterior surfaces every few years as necessary.

Maintenance Tips for Longevity

Monitor cement boards and gently rinse them once or twice a year. Avoid harsh cleaners. Fill gaps promptly to keep out the water intrusion.

For exterior installations , what’s worth doing is a good trough system or something that slopes so the water can drain. Indoors, joints that were properly taped and sealed can last long.

Frequently Asked Questions (FAQ)

What thickness of cement board is best for showers?

Use 1/2-inch boards for walls and floors to prevent flexing.

Can cement board get wet?

Yes, but it is water-resistant—not waterproof. Always use a waterproof membrane.

Is cement board stronger than plywood?

Yes, especially for tile installations and wet environments.

Does cement board need a vapor barrier?

A surface-applied waterproof membrane works best.

Can I paint cement board?

Yes, but always apply a primer first.

What’s the difference between cement board and fiber cement siding?

Cement board is thinner and used as a backing material. Fiber cement siding is thicker and designed for exposed exterior walls.