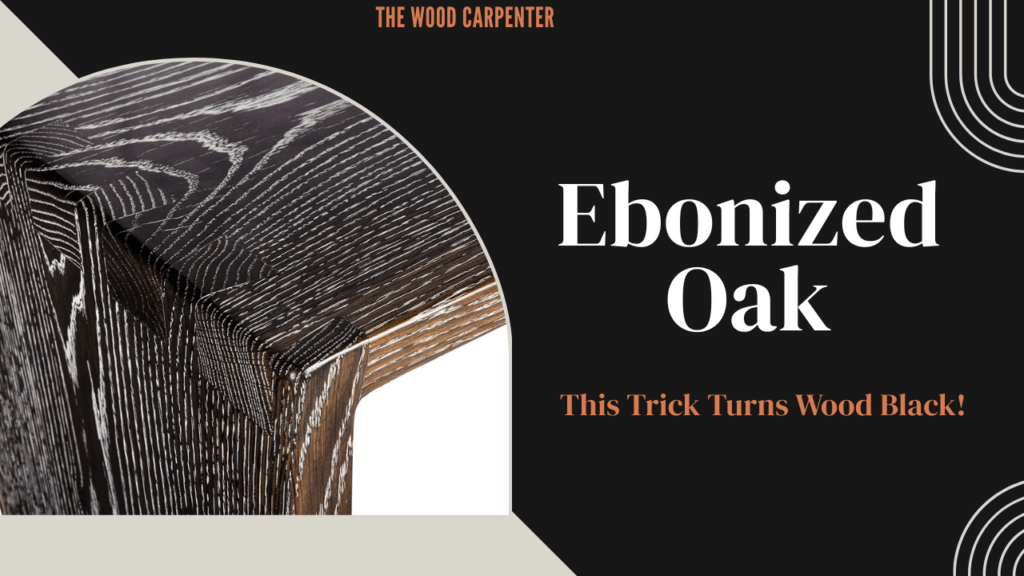

A special wood finish called ebonized oak actually completely changes the look of oak. Typical oak is light brown, strong and common. It ends up deep black, rich and elegant very similar to the expensive ebony wood – after it’s made ebonized.

This is not paint. It is not stain. And it is not a surface coating.

Ebonizing occurs via a chemical change within the wood which is why it lasts so long and looks natural for as long as anything.

This technique began in 17th-century Europe. By that time, real ebony wood had become very expensive and rare to find. Woodworkers found a smart solution. They found that when the oak is exposed to iron, it turns black on its own. This lent the wood a dark appearance without rare woods involved.

Today, ebonized oak is popular again. You can see it in modern furniture, luxury homes, floors, kitchens, and even musical instruments.

It’s popular because it offers a sharp black color but preserves the natural woodgrain, which paint of course does not.

What Does Ebonizing Really Mean ?

To ebonize is to make wood very dark so that it appears ebony.

Unlike black paint or stain, ebonizing changes the wood fibers themselves.

Oak is best, because it has a lot of natural tannins. When they meet iron, the tannins turn black within the wood.

This color does not peel, crack, or chip. Instead, it wears slowly and evenly over time.

White oak usually gives the deepest black color.

Red oak is great, too, but the black might I have noticed appear a little warmer with more defined grain lines.

Why Ebonized Oak Is Better Than Paint or Stain

Paint covers wood.

Stain colors wood.

Ebonizing transforms wood.

Because the black color goes inside the wood, the grain stays visible. You can still see and feel the texture of oak. This gives the wood a rich and natural look instead of a flat one.

Ebonized oak is also very strong. Oak keeps its natural hardness while getting the dark look of ebony. Ebony is harder, but it is also very expensive and difficult to work with.

Small scratches are less noticeable on ebonized oak. Wear blends in nicely, making it perfect for tables, cabinets, and floors.

The Simple Chemistry Behind It

Traditional ebonizing uses a liquid called iron acetate.

It is made by soaking steel wool in white vinegar.

The vinegar pulls iron from the steel. When this liquid is brushed onto oak, the iron reacts with the tannins in the wood. The wood turns black almost immediately.

No dyes. No paint. No color added on top.

Just a natural chemical reaction.

Woods with fewer tannins, like maple, may need black tea first to add tannins. Oak usually does not need this step.

Simple Steps: How Ebonized Oak Is Made

The process is easy and beginner-friendly.

First, sand the oak until smooth (around 180–220 grit). Clean off all dust. Lightly wiping with a damp cloth and sanding again helps keep the surface smooth.

To make iron acetate, place plain steel wool in a glass jar and cover it with white vinegar. Leave it loosely covered for a few days. When the liquid turns dark, it is ready. Strain out any metal bits.

Brush the liquid evenly onto the wood. The wood will darken quickly. Let it dry for one to two hours. Apply more coats if needed. Most projects need two or three coats.

Let the wood dry fully for 24 hours. Some people wipe it with a weak baking soda solution to stop the reaction.

Finish the wood with shellac, oil, polyurethane, or wax to protect it.

Where Ebonized Oak Looks Best

Ebonized oak is great for dining tables, cabinets, chairs, and beds. It looks amazing with brass or bronze hardware.

As flooring, it adds drama and still holds up well to daily use when sealed properly.

Musical instruments like pianos and guitars use ebonized oak as a cheaper and more sustainable option than real ebony.

It is also used in doors, wall panels, kitchen islands, and built-ins. Designers love how it grounds bright spaces without looking fake.

Ebonized Oak vs Other Black Wood Options

| Feature | Ebonized Oak | Real Ebony | Black Stain | Ebony Veneer |

| Cost | Low | Very high | Low | Medium |

| Strength | Very strong | Extremely hard | Can wear | Thin |

| Grain Visible | Yes | Slight | Mostly hidden | Surface only |

| Easy to Work | Yes | No | Yes | Fragile |

| Eco-Friendly | Yes | Often endangered | Depends | Depends |

For most projects, ebonized oak is the best mix of beauty, strength, cost, and sustainability.

Finishing, Care, and Long Life

Shellac is often used first because it locks in color. Water-based finishes keep a clean look. Oil and wax give a softer, classic feel.

Care is easy. Dust with a soft cloth. Avoid strong cleaners. Wax finishes may need refreshing. Poly finishes need very little care.

Small scratches are easy to fix. Light sanding and spot treatment blend in well. Over time, the wood develops a soft, natural aged look.

With proper sealing, ebonized oak can last for generations.

Pros, Cons, and Woodworker Tips

Ebonized oak gives the look of ebony at a much lower cost. The grain stays visible, the color ages well, and the process is simple.

The main challenge is getting an even color. Always test on scrap wood first. For outdoor use, strong protective finishes are needed.

Many woodworkers suggest using quartersawn oak and applying thin coats for best results.

Common Questions

What wood is best for ebonizing?

Oak is the best because it has lots of tannins.

Does ebonizing weaken the wood?

No. The wood stays just as strong.

Is it safe for kitchen tables?

Yes, once sealed with food-safe finishes.

How is it different from painted oak?

Ebonized oak shows grain and ages naturally. Paint hides texture and chips.

Can plywood be ebonized?

Yes, if the top layer has enough tannins.

Can the color be removed later?

Only by sanding deep into the wood.

Final Thoughts

Ebonized oak shows that you don’t need rare or expensive wood to get stunning results. With simple materials and patience, normal oak becomes bold, timeless, and full of character.

Whether you are restoring old furniture or making something new, ebonized oak gives a natural black finish that looks better with age—and always feels real.