Mallets: Last month, I watched a friend struggle to put together flat-pack furniture with an ordinary hammer. Each blow was leaving marks in the wood,parts shifted out of place, and frustration kept growing. I handed him my rubber mallet and suggested, “Try these instead.”

The change was instant. Smooth taps, clean joints, no damage. That moment clarified one thing: Many people seriously underappreciate what you can do with a mallet.

A mallet may look like a hammer, but it behaves very differently. When you know when and why to apply one, your work gets easier, cleaner and a whole lot more stress-free. So for all the woodworkers, metalworkers or stoneworkers or leather crafters, or even just furniture-makers in their own home, having the right mallet is exactly what makes all the difference.

What Exactly Is a Mallet ?

A mallet is a striking tool designed to apply force without damaging the surface you are hitting. Unlike steel hammers that concentrate force into a small point, mallets spread the impact over a wider area. This reduces dents, cracks, and unwanted marks.

The biggest difference lies in the head material. Mallets are made from wood, rubber, plastic, nylon, rawhide, urethane, or soft metals like brass. These materials absorb shock and give slightly on impact. That “give” is what protects your work and your tools.

Think of it this way: a hammer is made to hit hard and fast, while a mallet is made to persuade things gently—or firmly—into place without leaving scars.

Why Choose a Mallet Instead of a Hammer ?

Steel hammers are excellent for nails and metal shaping, but they can destroy delicate work. A mallet lets you feel what’s happening with each strike. You can guide a chisel, seat a joint, or adjust a part without crushing fibers or cracking finishes.

Woodworkers use mallets to protect chisel handles. Tile setters use them to avoid breaking tiles. Mechanics use them to move parts without damaging expensive components. Once you use a mallet correctly, going back to a hammer often feels reckless.

Main Types of Mallets (Quick Comparison)

| Type | Head Shape | Weight Range | Common Uses |

| Joiner’s | Square / rectangular | 20–40 oz | Mortises, heavy chiseling, joinery |

| Carver’s | Round / cylindrical | 8–24 oz | Gouges, fine carving |

| Chisel | Compact square | 12–20 oz | Paring, dovetails |

| Dead Blow | Rubber or urethane | 16–48 oz | Assembly, no rebound strikes |

| Rubber | Soft round | 8–32 oz | Furniture, tiles, trim |

This table alone solves most confusion. Each type exists for a reason, and choosing the right one saves time and effort.

Also read:

Drum Sanders: Get Flat, Smooth Wood the Easy Way

Orbital Sander Secrets Pros Don’t Want You to Know

Understanding the Most Common Mallet Types

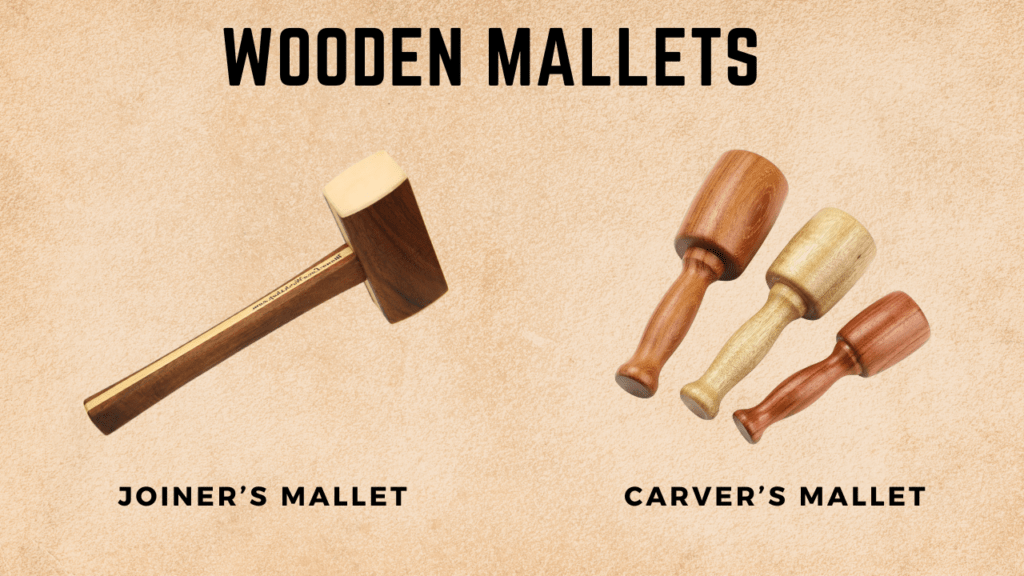

Wooden Mallets: The Traditional Choice

Wooden mallets have been used for centuries, and their design has barely changed because it works so well.

A joiner’s mallet has a square or rectangular head. It is heavier and ideal for chopping mortises, driving chisels, and assembling strong joints. The wide face forgives imperfect aim, which is helpful during heavy work.

A carver’s mallet has a round head that can be struck from any angle. This makes it perfect for carving where hand position changes constantly. These are usually lighter and allow long hours of controlled work.

Wood gives excellent feedback. You can feel each strike, which helps control depth and force. Over time, wooden mallets develop dents and marks, but that doesn’t reduce performance—it adds character.

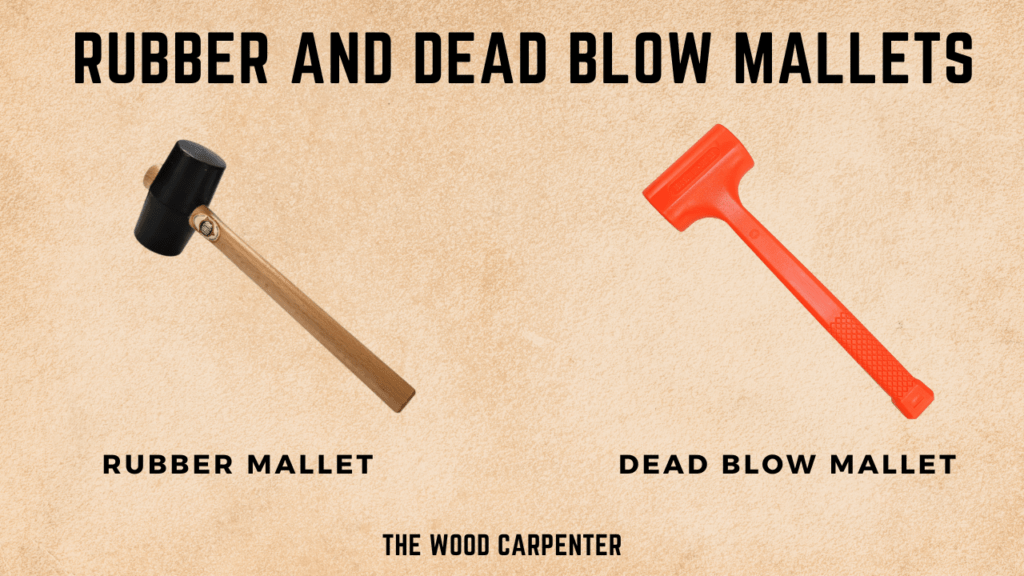

Rubber and Dead Blow Mallets: Modern Workhorses

Rubber mallets are everywhere because they are safe and versatile. They are perfect for furniture assembly, tile setting, trim work, and general adjustment tasks. The soft face protects finishes and edges.

Dead blow mallets take this idea further. They contain loose material inside the head that shifts on impact. This removes bounce and delivers more force in a single hit. Mechanics love them because one controlled strike often replaces several weaker hits.

Rubber mallets do wear out over time, especially in sunlight or extreme heat, but good-quality ones last for years.

Plastic, Nylon, and Urethane Mallets

Nylon mallets are harder than rubber and deliver more precise force. Jewelers and machinists use them when they need accuracy without metal damage.

Plastic mallets sit between rubber and nylon. Many come with dual faces of different hardness, giving flexibility in one tool.

Urethane mallets are extremely durable and resist chemicals, oils, and heavy wear. These are common in industrial and professional workshops where tools see daily use.

Rawhide, Leather, and Brass Mallets

Rawhide and leather mallets are favorites for delicate shaping. They hit firmly but don’t bounce, making them excellent for jewelry, leather stamping, and fine woodworking.

Brass mallets are used when more force is needed but steel would cause damage or sparks. They are common in automotive and machine shops.

Mallet Materials Explained Simply

| Material | Feel | Best Use | Drawback |

| Wood | Natural, responsive | Chisels, joinery | Can split over time |

| Rubber | Soft, forgiving | Assembly, tiles | Degrades with age |

| Nylon | Hard, precise | Metal, machinery | Slippery when wet |

| Urethane | Durable, strong | Heavy industrial use | More expensive |

| Rawhide | Firm, no rebound | Jewelry, leather | Needs care |

| Brass | Dense, controlled | Auto and machines | Heavy |

Each material exists to solve a specific problem. There is no “best” mallet—only the right one for the job.

Where Mallets Are Used in Real Life

- Woodworkers use mallets to drive chisels, seat joints, and assemble frames.

- Furniture builders rely on rubber mallets to protect finishes.

- Tile setters use them to level tiles without cracking them.

- Mechanics use dead blow mallets to loosen stuck parts.

- Leather workers use rawhide to stamp patterns cleanly.

- Jewelry makers shape precious metals without marking them.

If controlled force is needed, a mallet is usually the answer.

Choosing Your First Mallet

For most people, a medium-weight rubber mallet (12–16 oz) covers daily needs. If you work with wood, add a wooden joiner’s mallet. That simple pair handles almost everything.

The mallet should feel comfortable in your hand. If it feels too heavy, it will tire you out. Too light, and you’ll hit harder than needed.

Care and Maintenance

- Wooden mallets last decades if lightly oiled and kept dry.

- Rubber mallets should be stored away from sunlight.

- Plastic and nylon mallets need little care beyond cleaning.

- Rawhide mallets should be kept away from moisture and oils.

A well-maintained mallet can easily outlive many power tools.

Frequently Asked Questions

What’s the real difference between a hammer and a mallet?

A hammer concentrates force and damages surfaces. A mallet spreads force and protects them.

Can a mallet damage chisels?

No. That’s why they exist. Steel hammers damage chisel handles; mallets do not.

What’s best for IKEA furniture?

A rubber or dead blow mallet. Never use a steel hammer.

Are expensive mallets worth it?

Yes, if you use them often. They last longer and perform better.

Final Thoughts

Mallets may look simple, but choosing the right one changes how you work. They reduce mistakes, protect materials, and give you control instead of brute force.

Start with one good mallet. Learn how it feels. Over time, you’ll naturally add others as your work grows. The right mallet doesn’t just make tasks easier—it makes them cleaner, safer, and far more satisfying.

Once you understand mallets, you stop fighting your work and start guiding it.