A Simple Guide for Homeowners and DIY Lovers

If you’ve ever browsed a hardware store or built furniture yourself, chances are that you have encountered MDF boards — known as Medium Density Fiberboard — alongside pieces of plywood. These smooth brown boards are known as MDF.

MDF is used for most of the furniture in a typical house and office, such as cupboards and shelves, as well as tables, desks and chairs. But what exactly is MDF, its production process, how it compares against real wood or even plywood – or if at all – let’s keep things simple and find out.

Let’s keep things simple and find out.

What Is Medium-Density Fiberboard (MDF)?

MDF (Medium-Density Fiberboard) is a type of engineered wood. That means it’s man-made rather than cut directly from a tree. It’s created by breaking down small pieces of wood — usually leftovers like sawdust or chips — into fine fibers. These fibers are then mixed with glue (resin) and wax and pressed together under high heat and pressure.

The result is a strong, smooth, and even sheet of wood that doesn’t have knots or rough spots like natural wood. Because it’s so uniform, it’s very easy to cut, drill, paint, and shape — which makes it a favorite for both professionals and DIYers.

⚙️ How MDF Is Made — Step by Step

The process of making MDF might sound complex, but here’s the easy version:

- Collecting the Wood Fibers:

Leftover wood pieces, sawdust, and chips (often from sustainable sources) are gathered. - Breaking Down the Fibers:

The wood is broken into tiny fibers using special machines and steam. - Adding Resin and Wax:

These fibers are mixed with glue (usually urea-formaldehyde resin) and a bit of wax to make them strong and resistant to moisture. - Forming and Pressing:

The mixture is spread into flat sheets and pressed under very high heat and pressure to make it dense and solid. - Cooling and Sanding:

The large sheets are cooled, trimmed, and sanded smooth — ready to be used or laminated.

This process ensures that every MDF sheet has the same thickness, smoothness, and strength throughout.

🧱 Types of MDF Boards

There isn’t just one kind of MDF — different types are made for different uses. Here are the main ones you’ll find:

- Standard MDF:

The most common type, great for furniture, shelves, and indoor projects. - Moisture-Resistant (MR) MDF:

Made with special resins to resist humidity — ideal for bathrooms and kitchens. - Fire-Resistant MDF:

Treated with fire-retardant chemicals for safer use in offices or public places. - Ultralite MDF:

Lighter than regular MDF, easier to handle — perfect for large panels and display units. - Flexible (Bendy) MDF:

Can bend around curves — used for rounded furniture or wall designs. - Melamine-Laminated MDF:

Comes pre-covered with decorative sheets in many colors and patterns. Used in ready-made furniture and cabinets. - Exterior Grade MDF:

Treated to handle moisture outdoors — useful for signage or semi-outdoor furniture.

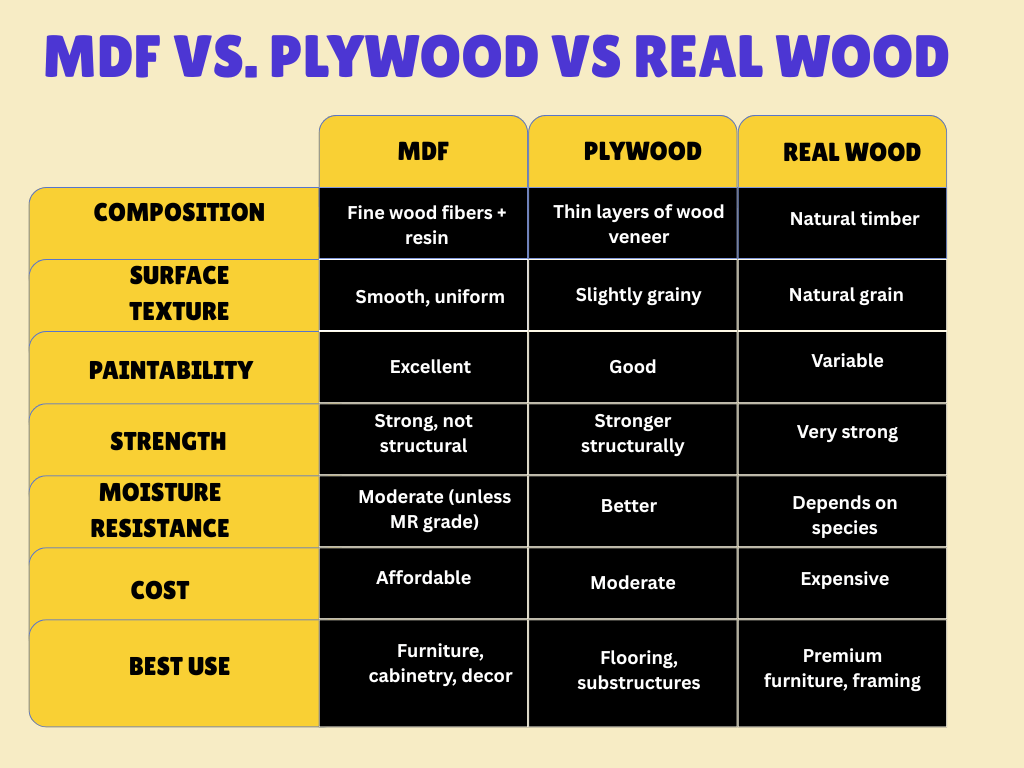

🪚 MDF vs. Plywood vs. Real Wood

Here’s the simple truth: each has its place.

- MDF is smooth, affordable, and great for painted finishes.

- Plywood is stronger and handles moisture better.

- Solid wood looks natural and lasts the longest, but it’s also the most expensive.

If you’re working on a budget or want a perfect painted look, MDF is your best friend.

💡 Benefits of MDF

So, why do so many people use MDF? Here are its biggest advantages:

✅ Affordable: It looks good and also it performs well at a much lower cost than the real wood.

✅ Smooth Surface: It has smooth sanded surface and no knots or grain, so it’s perfect for painting or laminating.

✅ Easy to Work With: Its natural structure makes for an ideal work cutting, drilling and shaping it without spitting.

✅ Eco-Friendly: Many of this MDF boards are made from the recycled wood fibers, so it helps in reducing the waste.

✅ Resistant to Termites: The glue and chemicals present in this will make them less appealing to the pests.

✅ Versatile: Use for furniture, panels, decorations, and even speakers.

✅ Uniform Quality: Each inch is identical, so there is no weak points or cracks.

⚠️ Disadvantages of MDF

No material is perfect. Here are a few things to keep in mind before using MDF:

🚫 Heavy: It’s denser and it is also heavier than plywood.

🚫 Sensitive to Water: Another difference is that regular MDF swells when you get it wet. Always seal it properly or use moisture-resistant types in humid areas.

🚫 Dusty When Cut: Cutting down this MDF creates fine dust so you make sure you wear a mask and ensure proper ventilation.

🚫 Not for Heavy Loads: It’s not strong enough for structural or load-bearing projects.

So by understanding these limitations you can work with the MDF safely and efficiently.

🏠 Common Uses of MDF

You’ll see MDF in a huge variety of applications in modern homes. Here’s how it’s used:

- Cabinets and Shelves: It is smooth and they are easy to paint.

- Furniture: Tables, dressers, wardrobes, and bookcases.

- Wall Panels and Wainscoting: It will add a texture and style to your walls.

- Trim and Moldings: It is ideal for detailed and decorative edge work.

- Doors and Frames: Doesn’t warp easily.

- Soundproofing: The density of it will also minimize the sound, so it will be good for your home studio or theater.

- Decorative Projects: Perfect fit for cutting with CNC machines, wall art design and display stands.

🌿 Is MDF Safe and Eco-Friendly?

The Modern MDF is considerably safer than its older ones. These days, most of the MDF is produced using the low-VOC, low-formaldehyde resins that adhere to the stringent regulations (like the CARB Phase 2 and EPA TSCA Title VI guidelines).

Many manufacturers also use the recycled or the sustainably sourced wood fibers — so MDF is considered to be a greener choice than cutting down the new trees.

You must also make sure to look for the eco-certification labels when buying — they ensure the boards are safe for you and our planet.

❓ Frequently Asked Questions

1. Is MDF as strong as wood?

Not quite. Real wood is stronger, but MDF is durable enough for most furniture and decorative projects.

2. Can MDF get wet?

Regular MDF can swell if wet. But moisture-resistant MDF (MR MDF) can handle humidity if properly sealed.

3. Is MDF safe for indoors?

Yes. Modern MDF has very low emissions and is safe when sealed and painted.

4. Can I recycle MDF?

Yes, though it’s a bit harder than recycling solid wood. Many factories reuse MDF waste.

5. How should I paint MDF?

First, seal the edges with primer, sand lightly, then paint in thin coats. MDF gives a beautiful, smooth finish when painted properly.

🧰 Final Thoughts

MDF has come a long way, but not just as a cheap wood imitation. Today it’s a versatile, dependable and budget-friendly material for hundreds of home projects.

It does not matter whether you’re building a bookcase, remodeling your kitchen or doing some wall trämming, you can get a high-end look without the high cost of one if you use this MDF.

Just remember this: choose the right type, seal it well, and handle it safely.

With that, MDF could be your secret weapon to a stunning (and cost-effective) home refresh.