Whether you’re working on a DIY project, building furniture, or specifying materials for construction, the word plywood gets thrown around a lot. But what exactly is plywood? Why is it used? How is it made? And how do you choose the right type for your project?

In this article we’ll walk you through its history, how it’s manufactured, its uses, types, advantages/limitations, how to choose one, and plus an FAQ at the end to cover the common questions.

What Is Plywood?

At its simplest, plywood is a sheet‐material made by gluing together thin layers of wood — these thin sheets are called veneers or plies (hence the name “ply-wood”). What makes plywood more than simply many layers of wood glued together is the arrangement: the grains of adjacent layers are typically oriented at right angles or otherwise varied. That cross-grain construction gives plywood greater stability, strength and resistance to warping compared to a single thick piece of wood.

Because the material is engineered rather than natural solid timber, it opens up options for large sheets, consistent dimensions, and manufacturing at scale — which is why plywood is so common in construction, furniture, packaging and more.

Properties of Plywood:

| Property | Typical Range / Value | Description |

| Specific Gravity | 0.4 – 0.6 g/cm³ | Density relative to water |

| Tensile Strength | 27.6 – 34.5 MPa | Maximum stress in tension |

| Modulus of Rupture | 7 – 10 GPa | Flexural strength |

| Flexural Modulus | 8 – 10 GPa | Stiffness in bending |

| Compressive Strength | 31 – 41 MPa | Strength under compression |

| Shear Strength (in-plane) | 1.7 – 2.1 MPa | Resistance to sliding forces within layers |

| Coefficient of Thermal Expansion | ~6.1 µm/m°C (parallel to face) | Dimensional change per degree Celsius |

A Brief History of Plywood

It’s fascinating how something that seems so everyday has deep roots.

- The idea of bonding thin wood layers goes way back: archaeologists have found laminated wood in ancient Egyptian tombs.

- By the 17th-18th century, the Europeans (British, French) began experimenting with layered wood pieces.

- The modern concept of plywood — veneer sheets glued and pressed, with grains running crosswise for strength — started to take shape in the 1800s. For example, a patent in 1865 by John K. Mayo in New York described “cementing or otherwise fastening together a number of … sheets … with the grain of successive pieces … running crosswise…”

- In the U.S., commercial production of plywood for building material began in earnest by the early 20th century; one milestone: the standard sheet size 4 ft × 8 ft (~1.22 m × 2.44 m) was introduced around 1928.

- Technological advances in adhesives (for example, phenol‐formaldehyde glue) and veneer cutting (rotary lathes) transformed plywood into a large-scale, versatile material.

So when you buy plywood today, you’re using a material with more than a century of refinement behind it.

How Plywood Is Manufactured

Let’s walk through the standard process of how it’s made, and that will give you an understanding of what to look for when selecting your plywood.

1. Log Selection and Preparation

Plywood begins with a log. For both species (softwood or hardwood) the log must be basically sound, straight-grained, free of large knots and perfect for veneer production.

2. Debarking and Conditioning

The log’s bark is removed; often the log is conditioned — sometimes steamed or soaked — to make it easier to peel without splitting or producing defective veneer.

3. Peeling/Slicing Veneers

This is the heart of the process. A rotary lathe (or other veneer-cutting machine) will peel the log to produce long thin sheets of veneer. Each sheet is clipped to size, any defects trimmed out. Because the sheets are very thin (often 1 to 4 mm depending on use) this step requires precision.

4. Drying the Veneers

After peeling, the veneers still contain moisture. To ensure the plywood will bond well, resist warping, and perform in varied conditions, the veneers are dried to a target moisture content.

5. Gluing and Layering

Here the veneers are coated with adhesive. The veneers are stacked in layers (“plies”) usually with the grain of each adjacent layer at right angles (or an alternate pattern) to the previous. This cross-grain structure gives the plywood much of its characteristic strength and dimensional stability.

6. Pressing (Cold then Hot)

Once the veneers are stacked, they are pre-pressed (cold press) to set the adhesive and flatten the assembly, then hot pressed under heat and pressure so the glue cures and permanently bonds the layers into a panel.

7. Trimming, Sanding, Quality Check

After pressing, the large sheets are cut/trimmed to standard sizes, sanded to smooth surfaces (especially for face/back veneers), and inspected for defects (voids, delamination, bonding strength, veneer defects).

Why Choose Plywood? (Advantages)

Plywood has some familiar advantages in comparison to plain lumber or other panel products:

- Dimensional stability: Because of the cross-laminated structure, it prevents the wood from warping or shrink/swell with temperature changes.

- Strength and load-bearing ability: Properly made plywood good plywood is capable of bearing heavy loads, holding nails and screws firmly and staying rigid as a floor or wall.

- Large sheet sizes & fewer joints: Using sheets (e.g., 4×8) it’s great to be able to cover big areas with fewer seams – it just looks better.

- Efficient material use: Veneer manufacturing allows use of smaller or faster-growing logs economically; also veneers enable for the better surface finishes (even exotic wood veneers) at lower cost than solid wood.

- Versatility: Used for construction, furniture, packaging, concrete formwork, shipbuilding, etc.

- Finishing flexibility: The surface veneer can be high quality (hardwood veneer) so it looks premium and can be stained, painted or laminated accordingly.

What Are the Limitations?

No material is perfect. There are a few caveats with plywood:

- Quality varies widely: The performance of plywood depends a lot on the glue quality, veneer quality, number of plies, species of wood, defect control. Cheap plywood may delaminate, warp, or have voids in the core.

- Edge finishing: The edges of plywood reveal layers/plies; sometimes that needs edge-banding or finishing to look good.

- Moisture concerns: Plywood (unless specifically rated for it) will not hold up long-term in moisture, and can swell, delaminate or rot.

- Cost vs alternatives: Cheaper panel products (OSB, MDF and particle board) could be adequate for some applications while performance trade-offs should be considered.

Types of Plywood & Their Uses

Plywood comes in several different types. We’ll make sense of them in plain terms.

Based on Wood Species / Strength:

- Softwood plywood: Usually it is made from conifer species (pine, fir, spruce). Often they are used for the structural applications like sheathing, flooring, wall panels.

- Hardwood plywood: They are made from deciduous species (oak, maple, birch, mahogany) – often used for furniture, cabinetry, decorative panels where appearance matters.

Based on Application / Environment:

- Interior / general-purpose plywood: Standard adhesives, for dry indoor conditions (furniture, interiors)

- Exterior or weather-resistant plywood: Uses water-resistant adhesives (phenol-formaldehyde or melamine glue) and intended for outdoor or wet conditions (roof decking, siding)

- Marine plywood: Highest grade; hardwood veneers, void-free core, waterproof glue; used in boats, docks, wet environments.

Based on Core Type & Construction:

- Veneer‐core plywood: Most common: all layers are veneers

- Lumber‐core plywood: Core made of small pieces of wood (boards) glued, then faces of veneer – higher nail/screw-holding capacity

- MDF-core plywood or composite core: For specialized uses (painted surfaces, smooth large panels)

Based on Number of Plies / Thickness:

Plywood sheets are described by how many layers (plies) and the overall thickness. Fewer plies = thinner sheet, usually for light duty. More plies/higher thickness = stronger, heavier duty.

How to Choose the Right Plywood

When you’re heading to a lumber yard or ordering plywood online., here are key things to check:

- Grades & label: Look for the face/back grade (A/B, C/D, etc), glue or exposure rating (interior, exterior, marine).

- Species / veneer quality: For visible surfaces (furniture, cabinetry) you’ll want high quality hardwood veneer, minimal knots/defects.

- Core/voids & plies: Inspect the edges if it is possible. Good plywood will have minimal voids; consistent plies; no gap between the layers.

- Adhesive/exposure rating: If you think that the plywood might get damp, then it is good to go for the exterior or marine grade with waterproof glue.

- Size & thickness: The standard U.S. sheet is 4 ft × 8 ft; thickness matters (⅜″, ½″, ¾″, etc) depending on the structural needs.

- Finish / surface smoothness: Especially if you’ll stain or paint the surface.

- Manufacturer/trustworthy brand: Plywood from well-established mills with proper quality control will perform good and better.

- Purpose matching: Don’t over-spec (and thus overpay) for a simple job; but also don’t under-spec for a critical structural or finish job.

Popular Uses of Plywood

Here are some typical applications where plywood shines:

- Construction sheathing (walls, roofs, floors): Plywood gives strong structural support and large sheet coverage, reducing joints.

- Furniture and cabinetry: Especially with hardwood veneer plywood, you can get beautiful appearance with good durability.

- Interior wall paneling, ceilings: Plywood can be used as a finished surface or underlay.

- Concrete formwork and industrial floors: Special film-faced plywood is used because of durability and re-use potential.

- Packaging and crates: For heavy goods transport, plywood provides strength and durability.

- Boat building / outdoor structures: When the correct marine plywood is used, it can stand up to moisture and outdoor conditions.

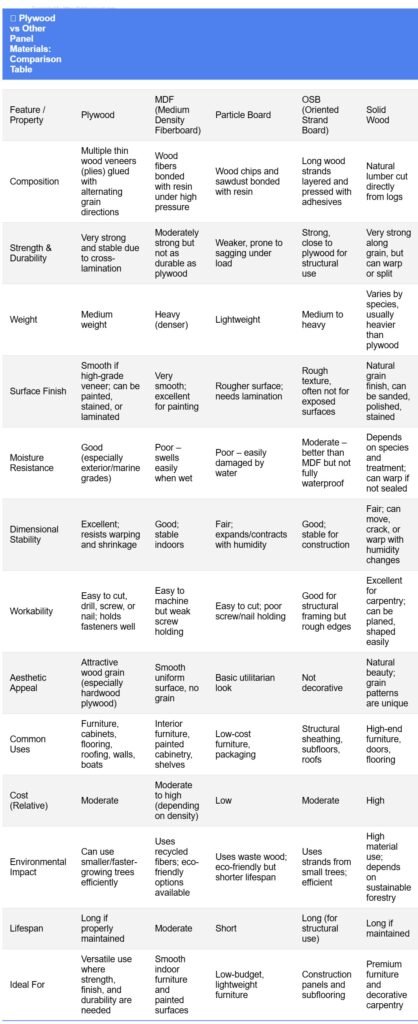

Plywood vs Other Panel Materials

Because you’ll often have choices, it’s useful to compare plywood with alternatives:

- Plywood vs Solid Wood: Solid wood is natural, but it can warp, shrink or crack. Plywood offers greater stability and larger sizes, often at lower cost per usable area.

- Plywood vs MDF/Particle Board: MDF sheets are more affordable compared to plywood, but they have a poorer load bearing and it has a lower moisture resistance. Plywood is stronger and more reliable structurally.

- Plywood vs OSB (Oriented Strand Board): OSB is generally used for sheathing and is a less expensive product; plywood often provides better surface quality, aesthetics and some performance benefits, but cost varies by species/grade.

- Plywood vs Laminated Veneer Lumber / Engineered Panel Products: For some applications you can choose the LVL or other engineered wood—but for many sheet uses plywood remains versatile and cost-effective.

Frequently Asked Questions (FAQ)

Q: What does the word “plywood” literally mean?

A: The “ply” in plywood refers to the thin layers (plies) of veneer that are glued together. “Plywood” means that the wood made of plies or layers.

Q: Is all plywood waterproof?

A: No—only plywood rated for exterior or marine use is designed for wet exposure. Standard interior plywood is not guaranteed to be waterproof. The glue type and core quality matter.

Q: What do the grades (A/B, C/D) mean?

A: These refer to surface veneer quality (face/back). For example, “A” grade face means very few defects, minimal knots; “D” would allow many more visual defects. The back grade may be lower. For structural uses, you might accept lower face grade if finish is not visible.

Q: How thick is plywood?

A: In the U.S., the typical thicknesses are ⅜″, ½″, ¾″, 1″ and up. The thickness is specified depending on load, span, application. Standard sheet size is 4 ft × 8 ft (1.22 m × 2.44 m).

Q: Can plywood be used outdoors?

A: Yes, if you choose the plywood that is rated for exterior use purpose or for the marine use, and if you apply proper finishes (sealants, paint, etc). Standard plywood may not last outdoors.

Q: What species of wood are used in plywood?

A: Both softwoods (pine, spruce, fir) and hardwoods (oak, maple, birch) are used depending on the type and application.

Q: Why does plywood cost more than particle board?

A: Because the manufacturing process of the plywood is more complex (veneer production, quality control, better adhesives), and this plywood offers superior performance (strength, stability, durability). You’re paying for performance.

Q: How do I know if the plywood I buy is good quality?

A: Check for minimal voids at the edges, consistent plies, smooth surface veneer, grade stamps (mill ID, rating, glue rating), and if possible buy from a reputable supplier/manufacturer.

Final Thoughts

If you’re seeking a workhorse sheet good that offers both strength and finish options, along with the ability to be shaped easily, plywood is hard to beat. It’s been around for a long time; manufacturing processes are well understood, and you have the variety of types today so that you can chose one that matches your budget and application.

For structural uses, pick plywood rated for load/structural use. For furniture and visible surfaces, invest in high-quality hardwood‐veneer plywood with a good finish. And for outdoor or wet uses, get exterior or marine-grade plywood, seal it properly, and you’ll have a reliable material for years to come.

The takeaway: plywood isn’t just “sheet wood” — it’s an engineered, well-tested product, and while you may not understand everything about what makes one sheet better than another, having a bit of background knowledge can give you the confidence to make a decision and get the most from what you buy.