Cross-Laminated Timber, often abbreviated as CLT, is rapidly transforming the world of construction. As architects, builders, and developers push toward more sustainable and efficient methods, CLT stands out as a remarkable alternative to conventional materials like concrete and steel. .

In this post, we’ll take a closer look at what exactly CLT is, how it’s manufactured, the pros and cons over other materials, practical applications in real-world projects and why it’s taking an increasingly significant role within green building in America.

What Exactly Is CLT?

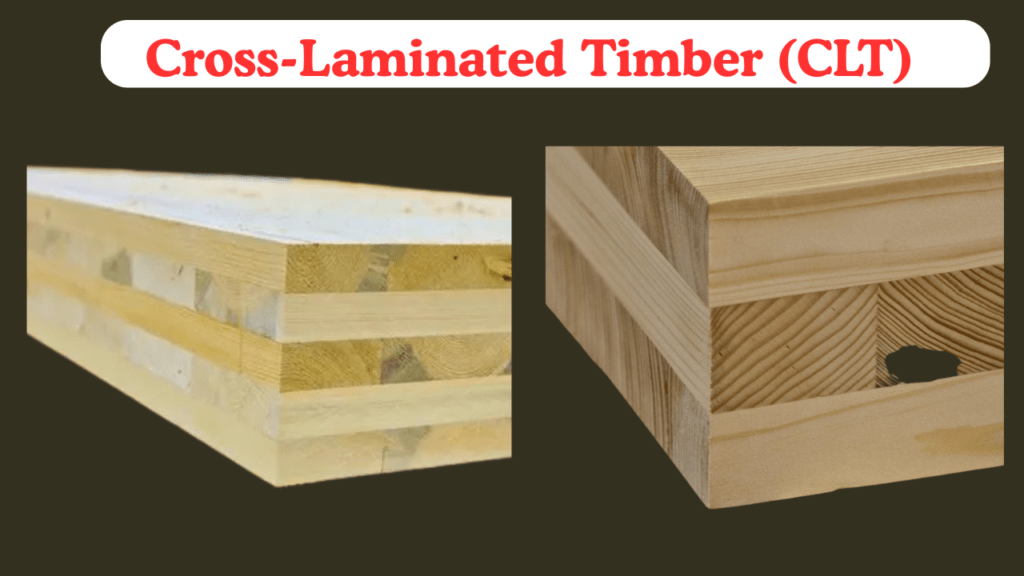

At its core, Cross-Laminated Timber is an engineered wood panel made by gluing together several layers (usually at least three) of solid-sawn lumber, with each layer oriented at right angles (90°) to the adjacent ones. This cross-wise arrangement gives the material exceptional dimensional stability and strength.

Unlike thin plywood veneers, CLT uses much thicker “lamellae” — resulting in panels that can serve as structural walls, floors, and roofs.

How Is CLT Made? (Step by Step)

Knowing how it’s made is key to understanding why CLT is so strong and holds up so well, in ecological and structural terms:

1. Lumber Selection & Drying

Producers begin by selecting high-quality solid-sawn lumber, often softwoods such as spruce, pine, or fir. The wood is kiln-dried to reach a target moisture content (around 12%) to reduce internal stresses and ensure stable bonding.

2. Planing & Cutting

The boards are planed for smoothness. Sometimes, finger joints are used to join shorter boards into longer lengths for uniformity.

3. Adhesive Application

Structural adhesives (commonly polyurethane-based) are applied between layers to bond them securely.

4. Lay-Up & Pressing

The boards are stacked in alternating directions, then pressed using hydraulic or vacuum presses. This ensures a strong, uniform bond.

5. Quality Control & Finishing

Once bonded, the panels are cut to size (often by CNC machines), and openings like windows or door spaces can be pre-cut off-site.

6. Shipping

Finished panels are transported to the construction site, often after being marked for installation.

Why Builders Love CLT: Key Advantages

CLT isn’t just another engineered wood — it offers a suite of benefits that make it compelling for modern construction.

1. Environmental & Carbon Benefits

- Carbon Sequestration: Trees absorb CO₂ as they grow, and when their wood is used in CLT panels, much of that carbon remains locked in for as long as the building stands.

- Lower Embodied Energy: Manufacturing CLT tends to use less energy than producing concrete or steel.

- Sustainable Forestry: When sourced from well-managed forests, the timber cycle can be quite sustainable, creating a circular carbon economy.

- Minimal Waste: Prefabricated panels reduce on-site waste. Offcuts or sawdust are often reused for other products, like biofuel or particleboard.

2. Speed & Efficiency of Construction

- Prefabrication Advantage: CLT panels are manufactured off-site and delivered ready to install, which significantly reduces construction time and labor.

- Lightweight: Despite being strong, CLT is much lighter than concrete or steel, leading to smaller foundation needs and easier transport.

- Precision: Since panels can be CNC-cut, designs can incorporate pre-cut window or door openings, minimizing on-site cutting and waste.

- Labor Efficiency: Because the panels arrive as complete elements, the need for highly specialized on-site labor is reduced.

3. Structural Strength & Stability

- High Strength-to-Weight Ratio: CLT delivers exceptional strength relative to its weight.

- Dimensional Stability: The alternating grain orientation makes CLT resistant to warping, shrinking, or swelling with moisture fluctuations.

- Seismic Performance: Because it is strong yet lightweight, CLT buildings perform impressively during earthquakes.

- Rigidity: The panel structure helps create strong diaphragms (floor, wall, roof) with good in-plane and out-of-plane stiffness.

4. Fire Performance

One of the most surprising (yet vital) benefits of CLT is its fire resistance:

- When exposed to fire, the outer layer chars and forms a protective barrier. This char layer insulates and slows down heat reaching the inner core.

- In lab tests, CLT panels have withstood more than 90 minutes of burning without catastrophic structural failure.

- This predictable burn behavior allows for safer evacuation, and in many cases, additional fire protection (like drywall) can be added to meet local codes.

5. Thermal & Acoustic Performance

- Thermal Insulation: Wood is naturally a good insulator, and the layered structure of CLT further improves its thermal mass and airtightness, helping reduce energy demands.

- Acoustic Benefits: CLT’s density and mass help dampen both airborne noise (voices, music) and impact noise (footsteps), making it ideal for apartments, schools, offices, and other shared spaces.

- Natural Interior Aesthetic: Exposed CLT gives interiors a warm, natural look — blending structural necessity with beauty.

Also read:

The Ultimate Guide to Woodworking: Types of Wood

Applications: Where CLT Shines

Because of its versatility, CLT is being used in a wide variety of building projects:

- Residential: Single-family homes, modular housing, and multi-family buildings benefit from CLT’s prefabrication, strength, and sustainability.

- Commercial & Office Spaces: Large floor plates of CLT offer open, flexible layouts. Think coworking spaces, startups, and even timber high-rise offices.

- Public & Institutional Buildings: Schools, libraries, and community centers take advantage of CLT’s acoustic and environmental performance.

- Hybrid Structures: CLT can be combined with steel or concrete in hybrid systems, leveraging the strengths of both materials.

- Mid- and High-Rise Buildings: Thanks to building code advances, CLT is now used in timber towers. The 2021 International Building Code (IBC) allows CLT in up to 18-story buildings under certain classifications.

A great example: Albina Yard in Portland, Oregon, was one of the first U.S. buildings to use a domestically manufactured CLT structural system.

Challenges & Considerations

Despite its many benefits, CLT isn’t a silver bullet. There are real considerations to keep in mind:

- Cost

- Upfront material costs can be higher compared to traditional framing, though this can be offset by savings in labor, time, and foundation.

- Transportation of large panels (especially long ones) can be expensive, due to size and weight.

- Code & Insurance

- While building codes (like the IBC) now support CLT, not all local jurisdictions or insurance companies have full experience with it.

- Insurance premiums can be higher, especially for taller timber buildings, because of perceived risk.

- Moisture & Weather

- During transport and on-site, CLT panels must be protected from moisture to avoid swelling or damage.

- Long-term moisture management is critical. If water seeps in, it can degrade the wood or adhesives.

- Long-Term Durability

- Some certification or testing bodies estimate a minimum service life of around 60 years for CLT.

- However, with good design and maintenance (especially protecting from moisture), buildings can last significantly longer.

- Fire Perception

- Though CLT performs very well in fire, there are public perceptions (and regulatory hurdles) to overcome. Designers often pair it with fire-resistant finishes to reassure stakeholders.

- Pest Exposure

- In some climates, insects like termites could be a concern. Proper treatment and design are required to mitigate this risk.

Why CLT Matters for the U.S. & Global Climate Goals

- Carbon Reduction: As the construction industry searches for greener materials, CLT’s ability to store carbon makes it a powerful tool to cut embodied carbon in buildings.

- Sustainable Development: Prefabrication and efficient use of materials support a more circular, less wasteful construction industry.

- Resilience: Lightweight but strong, CLT could contribute to more resilient buildings in earthquake-prone regions.

- Aesthetic & Well-Being: Natural wood interiors are not just beautiful — studies suggest they improve occupant comfort, reduce stress, and bring a biophilic connection to nature.

Real-World Examples & Milestones

- Albina Yard (Portland, OR): A four-story office building that helped demonstrate CLT’s viability in U.S. construction.

- IBC Updates: The 2021 International Building Code now formally allows CLT in Type IV-A, IV-B, and IV-C buildings up to 18 stories, reflecting growing trust in mass timber.

- Case Studies Worldwide: Across Europe and North America, CLT is being integrated into mid-rise buildings, modular construction, and hybrid timber towers.

Common Questions (FAQ)

Q1: Is CLT safe in a fire?

A: Yes — thanks to its char layer. When exposed to fire, the outer surface of a CLT panel chars, insulating the inner core.

In many tests, well-designed CLT structures have maintained structural integrity for 90+ minutes. Additional protection (like drywall) can further improve fire resistance.

Q2: How does CLT perform in earthquakes?

A: Very well. Because CLT is light but strong, it reduces the seismic forces that act on a building. Its cross-laminated structure also helps with stiffness and energy dissipation.

Q3: Can CLT sequester carbon?

A: Absolutely. Trees naturally absorb CO₂, and when used in CLT panels, much of that carbon remains stored in the wood for decades, making CLT a key player in low-carbon construction.

Q4: Is CLT more expensive than traditional materials?

A: The raw cost can be higher, but savings come from prefabrication, reduced labor time, lighter foundations, and faster construction. Plus, environmental and lifecycle savings can be significant.

Q5: What about durability? How long does CLT last?

A: Certification testing commonly assumes a service life of 60 years, but with proper moisture management, design, and maintenance, many experts believe it can last much longer.

Q6: Is CLT approved in U.S. building codes?

A: Yes. CLT manufactured to the ANSI/APA PRG 320 standard is recognized in the 2015 National Design Specification (NDS) and in the 2021 IBC for certain building types.

Best Practices for Designing With CLT

If you’re an architect, developer or builder considering other types of CLT, here are some practical things to keep in mind:

- Work with experienced mass-timber consultants: The design is not the same as traditional concrete/steel construction.

- Plan for moisture control: Appropriate sealing, design details and transport protection when they are designed and built.

- Think modular: Prefabricate panels with window/door openings, service channels and finishes to minimize on-site work.

- Pair with fire protection: Use fire-rated cladding or gypsum board where required to comply with code and stay safe.

- Optimize logistics: As CLT panels can be massive in size, consider for transportation, site access and crane picks.

- Choose sustainable sources: Utilize timber from well-managed forests to avoid environmental degradation.

The Bottom Line

Cross-Laminated Timber is more than just a trendy building material — it’s a structural and environmental game-changer. With superior strength-to-weight ratio, fire-resistant char performance, carbon-storing advantages and prefabricated efficiency, it would appear that CLT is primed to become a popular sustainable construction option.

For builders and developers in the United States, CLT is a way to construct greener, faster buildings that are also more resistant. As building codes change and production gets more affordable, mass timber may very well redefine what we conceive of as “modern construction.”