Dovetail saws are important tools in fine woodworking. They are known for making very precise cuts and are especially useful for making dovetail joints—a classic and strong way to join pieces of wood.

Whether you’re new to woodworking or have been doing it for years, learning how to use a dovetail saw properly can help you make cleaner joints and improve your skills.

This simple guide will cover the history, design, types, how to use and care for a dovetail saw, and tips to help you get the best results.

What Is a Dovetail Saw?

A dovetail saw is a small saw with a short, thin blade and a strong back (called a spine) that keeps the blade stiff for better control. It’s made for making very accurate cuts, especially when making dovetail joints. The teeth of the saw are usually shaped for cutting along the wood grain, which is perfect for this kind of joinery.

Key Characteristics :

Blade: Thin and short for delicate, controlled cuts.

Back/Spine: Metal or composite reinforcement for rigidity.

Teeth: Fine, with 14–20 teeth per inch (TPI) for smooth, accurate cuts.

Handle: Often a pistol grip for ergonomic control, though some have straight handles for lighter, more delicate work.

A Brief History

Dovetail saws come from a type of saw called a backsaw, which has been used since at least the 1700s. One of the first known makers was Robert Dalaway from Birmingham, England, who made saws in the late 1700s. His designs helped shape how dovetail saws look and work today.

Over the years, improvements in the handle shape, blade material, and tooth design have made modern dovetail saws more comfortable to use and more accurate than older versions.

The Anatomy of a Dovetail Saw

Understanding the parts of a dovetail saw can help you appreciate its design and functionality.

Blade

The blade of a dovetail saw is typically thinner and narrower than most other saws, allowing for fine, detailed cuts. It often has a relatively high TPI (Teeth per Inch), making it well-suited for clean, smooth cuts that don’t splinter the wood.

Handle

The handle of a dovetail saw is generally small and designed for control. It can be made from a variety of materials, including hardwood, plastic, or metal, and is ergonomically shaped to give you a comfortable grip during use.

Kerf

Kerf refers to the width of the cut made by the saw. Dovetail saws are designed to create a narrow kerf, which helps in making precise, clean cuts without wasting material.

Also read:

Expansive Bit Explained: The Ultimate Woodworker’s Guide

Hand Planing Wood: Simple Tips for Everyone

Dovetail Saw vs. Other Backsaws

| Feature | Dovetail Saw | Carcass Saw | Tenon Saw |

| Blade Length | 6–10 inches | 10–14 inches | 12–16 inches |

| Plate Thickness | Thinner (approx. 0.015″) | Medium (approx. 0.020″) | Thicker (approx. 0.025″) |

| TPI | 14–20 | 12–14 | 10–12 |

| Tooth Profile | Rip (for with-the-grain cuts) | Crosscut or Rip | Rip |

| Best For | Dovetail joints, fine joinery | Carcass joinery, small tenons | Large tenons, deep cuts |

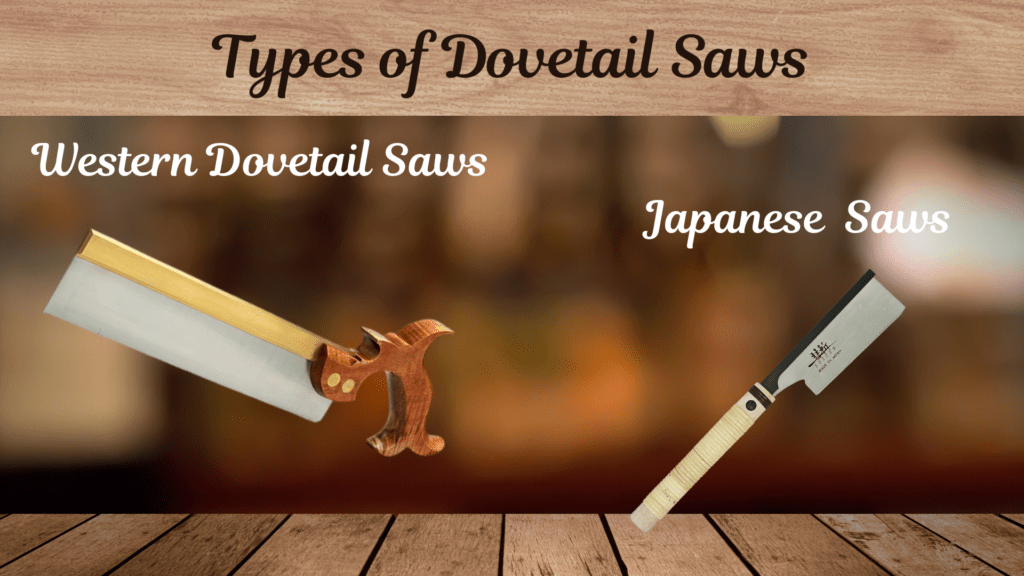

Types of Dovetail Saws

Western Dovetail Saws

Push Stroke: Cuts on the push stroke, with a rigid spine and often a pistol grip handle for ergonomic comfort.

Blade: Thicker and heavier than Japanese saws, allowing for easy resharpening and maintenance.

Popular Brands: Lie-Nielsen, Veritas, Gramercy Tools.

Japanese Dozuki Saws

Pull Stroke: Cuts on the pull stroke, keeping the blade in tension for a thinner, faster cut.

Blade: Extremely thin and hard, often with replaceable blades due to sharpening difficulty.

Teeth: Higher TPI (16–30), resulting in very fine cuts.

Choosing the Right Dovetail Saw

Factors to Consider:

TPI (Teeth Per Inch): More teeth mean smoother cuts but slower progress. For most dovetail work, 14–20 TPI is ideal.

Blade Thickness: Thinner blades yield finer kerfs and more precise joints, but can be more prone to flexing if not handled properly.

Handle Design: Pistol grips are common for comfort and control, but some prefer straight handles for lighter, more delicate work.

Weight and Balance: Heavier saws can help with cutting momentum, while lighter saws offer more feedback and control.

Price and Quality: Higher quality saws offer better steel, more precise teeth, and more comfortable handles, but even budget saws can perform well with proper sharpening.

How to Use a Dovetail Saw Like a Pro

Mark Your Lines: Use a sharp marking knife and square to lay out your dovetails precisely.

Body Position: Stand with feet apart, arm and saw aligned straight from shoulder to blade for maximum control.

Grip: Hold the saw lightly, guiding with your index finger along the side of the handle. Let the saw do the work—don’t force it.

Start the Cut: Begin with a few gentle strokes to establish the kerf, then proceed with steady, even strokes.

Sawing Technique: Keep the saw vertical and follow the marked line closely. Use the full length of the blade for smoother, straighter cuts.

Practice: Cutting straight lines on scrap wood is an excellent way to build skill and confidence.

Sharpening and Maintenance

Western Saws: Can be resharpened at home with a small triangular file. Most are filed with a rip tooth pattern for dovetailing.

Japanese Saws: Usually have hardened teeth that are difficult to sharpen; replacement blades are common.

Set and Kerf: Minimal set is preferred for dovetail saws to create a narrow kerf and tight joints.

Lubrication: A light coat of oil or beeswax on the blade can prevent binding and make sawing smoother.

Best Brands for Dovetail Saws

Some of the top brands for dovetail saws include:

- Lie-Nielsen

- Veritas

- Shark

- Japanese brands like Gyokucho and Suizan

These brands are known for their craftsmanship and high-quality tools that will stand the test of time.

Troubleshooting Common Problems

Wandering Cuts: Often caused by a dull blade, improper grip, or forcing the saw. Sharpen the teeth and focus on technique.

Binding: Can result from a blade with too much set or from sawing wet wood. Lubricate the blade and check the set.

Gaps in Joints: Usually due to sawing out of square or not following the layout lines precisely. Practice and check your work with a square regularly.

Common Mistakes When Using a Dovetail Saw

Cutting too fast: Rushing through a cut can lead to jagged edges and inaccurate joints.

Not using a square: Ensuring your cuts are perfectly perpendicular is crucial for making strong dovetail joints.

Over-tightening the saw: When using a dovetail saw, try not to grip the handle too tightly, as it can cause unnecessary strain and affect the quality of the cut.

Safety Tips

Always wear eye protection and keep your workpiece securely clamped.

Inspect the saw and wood for defects or embedded metal before cutting.

Use slow, controlled strokes, especially when starting a cut.

Conclusion

A dovetail saw is more than just a tool—it opens the door to careful and detailed woodworking. By learning about its history, design, and how to use it the right way, you can make tighter joints, smoother cuts, and enjoy your work even more.

Whether you pick a Western or Japanese-style saw, choose a good-quality one, take care of it, and keep practicing your skills. The real reward isn’t just the strong joints you make, but the skill and confidence you gain with every cut.

FAQs

Q1: What’s the difference between a dovetail saw and a regular saw?

A dovetail saw has finer teeth, a smaller size, and is designed for precision cuts, especially for dovetail joints, whereas a regular saw is usually used for larger, rougher cuts.

Q2: Can I use a dovetail saw for cross-cutting?

Yes, dovetail saws are perfect for cross-cutting, thanks to their finely filed teeth that work well across the grain of the wood.

Q3: How do I sharpen a dovetail saw?

You can sharpen a dovetail saw with a saw file, carefully filing each tooth to maintain the correct angle. It’s recommended to have it professionally sharpened if you’re unsure.

Q4: Is a Japanese dovetail saw better than a traditional dovetail saw?

It depends on personal preference. Japanese saws are generally lighter, thinner, and use a pull motion, while traditional saws use a push motion and offer a more controlled cut for some users.

Q5: What’s the best type of wood for dovetail joints?

Hardwoods like maple, oak, and cherry are best for dovetail joints, as they hold up well and provide a clean finish.