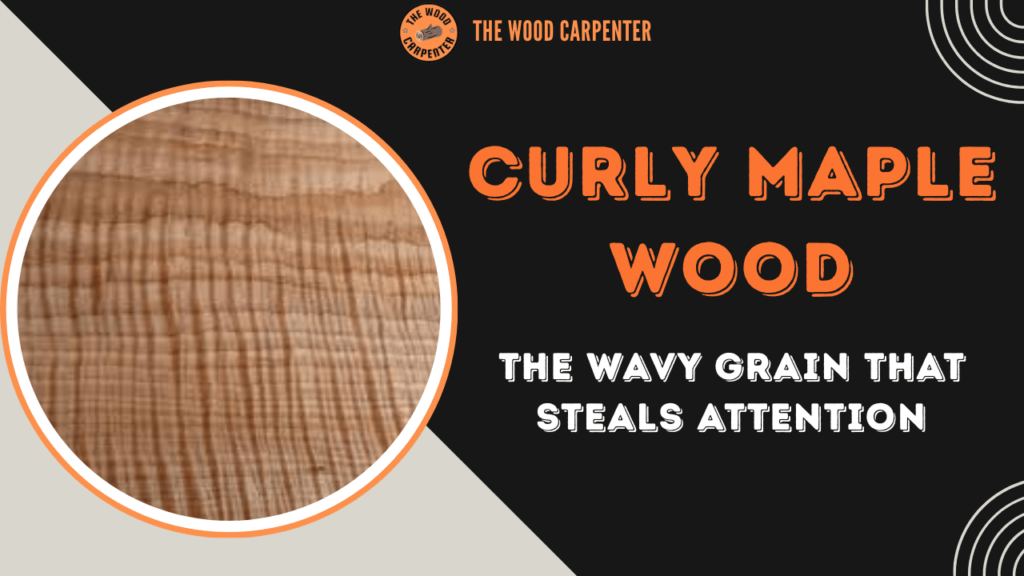

Curly maple wood is one of those material that really has this attention grabbing quality to it. The grain seems to shimmer and ripple as light passes over its surface, in a manner resembling water in motion.

This eye-catching effect helps explain why for centuries it’s been a favorite of furniture makers, instrument builders and collectors alike. From classic violins to luxurious furniture, this wood transforms ordinary objects into timeless works of art.

But curly maple isn’t just a pretty face. To use it well, you need to know what gives its famous figure, where it’s from and how to work with it in a right manner.

What Makes Curly Maple Special?

It is not actually a different species of tree, it’s just maple with distorted grain. It is harvested from the ordinary variety of maple tree, usually sugar maple but also red, black or silver maple.

What sets it apart is the direction in which the wood fibers are arranged. Instead of shooting straight, the fibers curl and curve under their the surface.

This creates a rippled pattern known as curl, which runs across the grain rather than along it. When the wood is cut, especially quartersawn, these waves become highly visible and produce a glowing effect called chatoyancy. As you move around the wood, light shifts across the surface, making the grain appear alive.

Colors usually range from creamy white to pale gold, slowly turning a warmer amber as the wood ages.

In terms of strength, curly maple shares the same properties as normal maple. It is resistant and tough, but the twisted grain is difficult to work.

Why Curly Maple Looks the Way It Does

No one can predict which maple tree will produce curly wood. The bark gives no reliable clues, and many figured logs are discovered only after cutting.

Most experts believe curly figure comes from a mix of genetics and natural stress. Trees growing on slopes, rocky ground, or windy areas sometimes develop uneven fiber growth. This irregular growth bends the wood cells, creating the wave pattern.

What’s certain is that the figure runs deep through the board. Even when carved or shaped, the pattern remains, which is why curly maple is so popular for sculpted work and instruments.

Types of Figured Maple You’ll Often See

Curly maple is the most common figured maple, but it has close relatives that are also highly valued.

- Fiddleback or Flame Maple shows tight, even stripes and is widely used for violins and guitars.

- Tiger Maple has wider, bolder stripes with strong contrast.

- Quilted Maple has a rounded, puffy pattern and is rarer than curly maple.

- Birdseye Maple features small circular marks scattered across the surface.

- Ambrosia or Spalted Maple shows natural color streaks caused by insects or fungi.

Each type has its own look, but curly maple remains the most versatile for furniture and instruments.

Physical Properties of Curly Maple

Curly maple looks delicate, but it is surprisingly strong. Its physical traits make it suitable for both beauty and function.

| Property | Value | Why It Matters |

| Dried Weight | 30–44 lbs/ft³ | Strong yet workable |

| Janka Hardness | 700–1,450 lbf | Resists dents and wear |

| Modulus of Rupture | 13,000–15,000 psi | Handles bending stress |

| Elastic Modulus | 1.8–2.0 million psi | Maintains stability |

Hard curly maple is preferred for musical instruments and gunstocks, while softer varieties are often used for veneers and decorative panels.

Where Curly Maple Comes From

Curly maple is native to North America, especially the northeastern United States and Canada. Sugar maple forests are the main source, though figured maple also appears in the Pacific Northwest from bigleaf maple.

Since figured wood is not very common, curly maple is usually harvested only from managed forests. Quality mills mill the lumber, kiln dry, and store it properly to retain this beauty.

Common and High-End Uses of Curly Maple

Curly maple is often saved for projects where appearance matters most.

Furniture makers use it on tabletops, drawer faces, cabinets and accent panels. A small piece can be the central point of a work.

Curly maple has been used for hundreds and hundreds of years in making instruments. Curly maple is also common in the backs of violins, guitars with curved sides, and the backs of mandolins. It projects sound nicely and adds some sophistication without affecting tone negatively.

Gunstocks are another classic use. Curly maple is very shock absorbent and beautiful with an oil finish.

It is also used for turning blanks, stair rails, flooring accents, knife handles, boxes, and decorative trim.

Buying Curly Maple: What to Look For

Quality curly maple is sold by specialty hardwood dealers, not hardware stores. Prices depend heavily on figure strength.

Mild curl usually costs $12–20 per board foot. Medium figure ranges from $25–35, while strong exhibition-grade curl can exceed $60 per board foot.

Always check moisture content. Properly kiln-dried boards should be around 6–8% moisture. Boards should be flat, free of deep cracks, and evenly figured.

Very cheap curly maple is often a warning sign. Poor drying, weak figure, or hidden defects are common at suspiciously low prices.

Working with Curly Maple Without Problems

Curly maple demands patience. The very grain that looks so pretty is also what causes tearout when planing or routing.

Sharp tools are essential. Light cuts, slow feed rates and careful sanding can help avoid that. Most woodworkers prefer scrapers over plane for final smoothing.

The sanding needs to be in stages (going down the grits gradually). And rushing this process usually results in scratches that show up when finish is applied.

Finishing Curly Maple for Maximum Glow

Curly Maple really comes alive with its finish. Since grain takes up finish unevenly, sealing the surface first helps prevent blotching.

Many artisans like oil finishes because they bring out richness and warmth . Shellac works well as a base coat, while polyurethane adds durability for furniture.

| Finish Type | Pros | Cons |

| Boiled Linseed Oil | Deep grain pop | Slow drying |

| Polyurethane | Tough and durable | Slight yellowing |

| Water-Based Finish | Clear, fast drying | Less depth |

| Shellac | Quick figure enhancement | Less durable alone |

Light sanding between coats and final buffing bring out the best shimmer.

Caring for Curly Maple Pieces

Curly maple pieces will last generations with a little bit of care. Gently dust, do not place in direct sunlight and keep indoor humidity consistent.

Furniture polish once or twice a year keeps finishes fresh.

Minor scratches should be repaired early to prevent deeper damage. High-value pieces may benefit from professional restoration.

Sustainability and Responsible Use

Sugar maple woodlands are sustainable, and curly maple itself can be sustainable if harvested responsibly. Purchasing from FSC-certified sources contributes to sustaining future forests.

Because figured wood is rare, many woodworkers save offcuts for small projects rather than wasting them.

Frequently Asked Questions

What causes curly maple’s figure?

It comes from twisted fiber growth caused by genetics and natural stress during the tree’s life.

Is curly maple harder than normal maple?

No. It has the same hardness as regular maple from the same species.

How much does curly maple cost in 2026?

Prices range from about $12 to $60+ per board foot, depending on figure quality.

What is the best finish for curly maple?

Sealing and then finishing with oil or polyurethane will give the most depth and shine.

Is curly maple sustainable?

Yes, as long as it’s sourced from sustainably managed forests in North America.

Why Curly Maple Never Loses Its Appeal

Curly maple can’t be replicated or duplicated exactly. Each board is unique, shaped slowly by nature over decades. That rarity, combined with its glowing beauty, keeps it in demand across generations.

Whether used in a violin, a table, or some small hand-made object, curly maple asks people to slow down and appreciate the every curve and sweep of its grain. In a world of rushed manufacture, perhaps that silent dignity is its biggest virtue.