Introduction: The Unsung Hero of Modern Construction

Walk into any construction site or home improvement store in the U.S., and there’s a good chance you’ll likely see large, speckled wood panels stacked in neat piles. That’s the Oriented Strand Board, or OSB—an engineered wood product which has quietly become a go-to material for builders, remodelers, and even DIYers.

It is considered to be the “cheaper alternative” to plywood, OSB has earned its place as a high-performance, sustainable building material. From the roofing usage and wall sheathing to flooring and furniture, this OSB offers strength, consistency, and cost savings that make it hard to ignore.

So what is OSB and why has it become so common? Let’s break it down.

What Is Oriented Strand Board (OSB)?

Oriented Strand Board (or simply OSB) is an engineered wood panel that is made from thin wood strands, from fast growing trees such as aspen, poplar or southern yellow pine. These strands are treated with waterproof, heat-cured adhesives and arranges in orientations that significantly enhance the structural properties of the panel (hence the name “oriented).

The outer layers of strands are typically aligned in the same direction as the panel’s length, while the inner layers are laid crosswise. This crisscross pattern gives the OSB its exceptional strength, stability, and resistance to warping qualities that make it perfect for the structural applications.

In short: OSB takes small, low-cost pieces of wood and turns them into something incredibly strong and uniform.

How Is OSB Made?

The process of making OSB is both high-tech and eco-friendly. Here’s a simple breakdown:

- Log Selection and Preparation – Manufacturers use smaller faster growing trees that may be too small for traditional sawmills to accept. The logs are then debarked and cut into long, thin strands (typically 3-6 inches).

- Drying and Blending – The strands are dried to a precise moisture level and then they are coated with a water repellant resin and wax.

- Forming the Mat – These coated strands are stacked into mats. The surface layers are aligned parallel to the length of the board, and the inner core plies run perpendicular to it for increased strength.

- Pressing Under Heat and Pressure – The Mat is then heat-pressed at high temperature and pressure. (Here, the adhesives are activated, bonding all together into a dense, rigid panel.)

- Cutting and Finishing – Once the panels are free of defects they’re cut, sanded, and trimmed to size (usually 4’x8’ in the U.S.). Many are stamped with codes for their performance rating, indicating how they can be used — for roofing, walls or floors.

This process not only makes them very strong, uniform material, but also it maximizes the wood efficiency — using nearly the whole tree.

Why OSB Became So Popular

By the early 2000s, OSB had overtaken the plywood as the most commonly used structural panel in North America. These days, most of the homes built in the United States incorporate OSB into some part of their structure — roof decks and subfloors as well as wall sheathing, to name a few.

Here’s why OSB won over builders and manufacturers:

- Cost-Effective: Typically, OSB boards are priced 20–30% cheaper than equivalent plywood boards.

- Consistent Quality: Because it’s engineered, OSB has fewer voids, knots, or weak spots.

- Larger Panel Sizes: Manufacturers can make OSB panels in sizes larger than standard plywood, which reduces seams and speeds up installation.

- Sustainability: OSB uses smaller trees and nearly 100% of each log, minimizing waste.

- Strength: Despite being cheaper, OSB can match (and sometimes exceed) plywood’s load-bearing strength.

OSB vs. Plywood: Which One’s Better?

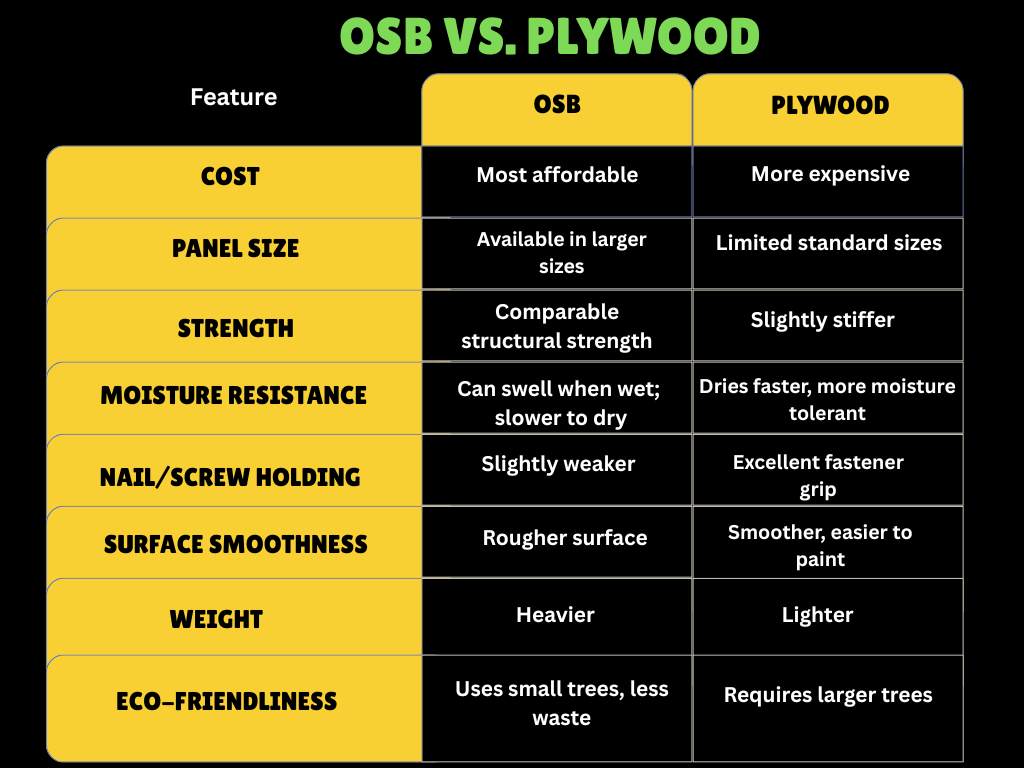

When comparing OSB and plywood, the truth is—they’re both strong contenders, but for different reasons. Let’s look at how they stack up.

👉 Bottom Line:

If you’re working on budget-sensitive or large-scale construction projects, OSB delivers outstanding value and consistency.

But if you need top-notch moisture resistance or a smoother finish (for cabinetry or exposed surfaces), plywood still has an edge.

Applications of OSB

OSB’s versatility is one of its biggest strengths. It is used in almost every area of residential and commercial construction as well as for furniture and packaging.

Here are some of the most common applications:

1. Wall Sheathing

OSB panels are used as structural sheathing for exterior and interior walls. They provide stiffness and enable the structure to resist wind and seismic forces. For locations likely to be affected by humidity or rain, we recommend OSB3 or even OSB4 grade.

2. Roof Decking

Builders like OSB, for instance, because it’s strong and uniform with no tendency toward splitting. And once properly sealed, it provides reliable performance under shingles and tiles.

3. Flooring and Subflooring

OSB panels provide a stable, level surface for floors. They’re especially popular for subfloors under carpet, vinyl, or hardwood. However, it’s important to use moisture-resistant panels in bathrooms or basements.

4. Furniture and Interior Design

In recent years, OSB has found a surprising place in modern furniture design. Its distinctive speckled texture gives an industrial, rustic aesthetic. You will see it in tables, cabinets, chairs and decorative walls.

5. Packaging and Industrial Use

Because OSB is so sturdy and cost-efficient, it’s used in making pallets, crates and industrial packaging.

Advantages of OSB

- ✅ Budget-Friendly: Significantly cheaper than plywood.

- ✅ Uniform Structure: No knots or gaps, offering consistent strength.

- ✅ Eco-Conscious Choice: Uses fast-growing species and nearly the whole log.

- ✅ Custom Sizes: Can be produced in large or custom dimensions.

- ✅ High Load-Bearing Strength: Perfect for heavy-duty construction works.

- ✅ Dimensional Stability: Slightly more resistant compared to solid wood.

Disadvantages of OSB

- ⚠️ Moisture Sensitivity: When they are repeatedly exposed to water over time, this OSB will get swollen — particularly in the edges.

- ⚠️ Heavier Panels: OSB is denser and they are heavier than the plywood, which may make it a little bit tricky to handle.

- ⚠️ Rough Surface: They are not suitable for fine finishing unless or until they are laminated or covered.

- ⚠️ Formaldehyde Emissions: Some OSB panels can off-gas VOCs, though many U.S. brands now meet CARB Phase 2 and EPA TSCA Title VI emission standards.

- ⚠️ Longer Drying Time: Once these OSB gets wet, it will take a longer time to dry out than the plywood.

Environmental Impact and Sustainability

Here’s something many people don’t realize: OSB is actually one of the most sustainable engineered wood products available.

It is made of smaller, faster-growing trees, which are often harvested from responsibly managed forests. The manufacturing process, which consumes almost every part of the log — wood chips and flakes included — is far less wasteful than traditional lumber production.

What’s more, the modern OSB production process in North America is designed to meet stringent environmental standards which lead to low emissions and small ecological footprint.

Tips for Using OSB Effectively

- Always seal edges if the panel might be exposed to moisture.

- Use moisture-resistant grades (OSB3 or OSB4) in humid or outdoor environments.

- Dry and Store OSB Panels Flat Prior to Using Them.

- Do not leave OSB panels exposed to the weather, rain or standing water for extended periods.

- Use approved fasteners and follow spacing guidelines for maximum structural integrity.

FAQs About Oriented Strand Board (OSB)

Q1. Is OSB waterproof?

No, OSB isn’t fully waterproof. It’s moisture-resistant to a degree but can absorb water if left exposed. Always protect it with sealants or use water-resistant grades.

Q2. Can OSB be painted or stained?

Yes! But because of its rough surface, it’s best to sand it lightly and use a primer before painting.

Q3. Is OSB stronger than plywood?

Structurally, OSB and plywood are comparable, though plywood offers better nail-holding and moisture resistance.

Q4. Does OSB contain formaldehyde?

Some OSB panels do, but most U.S. manufacturers now produce low-emission, CARB-compliant boards. Always check the certification before purchasing.

Q5. Can I use OSB for exterior projects?

Yes, but make sure you use an exterior-grade OSB with the proper weather protection or siding film.

Final Thoughts

OSB is more than a budget plywood alternative. It’s an intelligent, durable and structurally versatile material that fuels a lot of modern construction in the U.S. If you’re constructing a house, redesigning your attic or creating an earth-friendly piece of furniture, OSB has got you covered.

Handled properly and protected, it can last for generations and help you build smaller, greener, smarter and more affordably.