Ever considered how the material of your cutting board might impact your culinary experience? Selecting the appropriate wood for your cutting board goes beyond looks; it also depends on utility, durability, and maintaining sharpness of knives. Let’s explore why wood is the greatest option and how to choose the one suited for your purpose.

Why Wood is the Best Material for Cutting Boards:

Considering its many benefits over other materials, especially plastic, wood is generally considered as the ideal choice for cutting boards. The main reasons wood stands apart are the following:

Knife Preservation

Gentle on Blades: Wood cutting boards are softer to knife blades than plastic, so they are less abrasive. Longer knives’ sharpness is maintained in part by this mild surface, therefore lowering the rate of sharpening required.

Self-Healing Properties: Knives cutting into wood tend to seal the fibers around the cut, therefore reducing damage and enabling the board to retain its surface integrity over time.

Antibacterial Qualities

Research shows that wood has natural antimicrobial qualities. For example, compared to those on plastic surfaces, microorganisms put on wooden surfaces often die off faster. According to a study, 99.9% of the germs on wooden boards had perished in three minutes; those on plastic did not show such results.

The way wood is structured lets it trap bacteria in cuts and grooves, therefore locking them away from food contact.

Durability and Longevity

High-quality hardwoods including maple, walnut, and teak are long-lasting and, with proper maintenance, can endure many years. Their lifetime is much extended by sanding down severe cuts and scratches.

Comparatively to less expensive materials, well-made wooden boards are less likely to warping. Additionally stable throughout usage are thinner boards.

Aesthetic Appeal

Often times, wooden cutting boards seem better than plastic ones. They may improve the look of a kitchen and act as appealing serving platters too.

Sustainability

Compared to plastic, which adds to environmental contamination, wood is a renewable resource and biodegradable choice. Furthermore improving its sustainability profile are responsible purchasing methods.

Comparison with Plastic

Plastic cutting boards are convenient (they are dishwasher-safe), but they also dull knives faster and may hold germs in deep wounds that are difficult to fully clean. On the other hand, many chefs and home cooks choose wood because it offers a favored mix of usefulness, durability, and aesthetic appeal.

Characteristics of a Good Cutting Board Wood

Many factors decide a wooden cutting board’s quality and fit for usage in the kitchen. The key characteristics that require to give thought are these:

1. Wood Type

Hardwoods vs. Softwoods: Hardwoods like maple, walnut, and cherry—durable and mild on knives—are the greatest cutting boards. Often preferred as they are more gentle on knife edges and can tolerate deeper cuts without displaying wear,

2. Density and Hardness

Janka Hardness Rating: A higher Janka hardness rating denotes denser wood capable of superior resistance against cuts and scratches. For knives, woods like as maple (1,180 lbf) and beech (1,450 lbf) are well-known for their robustness but mildness.

Self-Healing Properties: Woods with high self-healing qualities, such maple or walnut, can mend small cuts over time, therefore preserving a smoother surface.

3. Water Resistance

Natural moisture resistance of the wood used to make a cutting board will help to prevent warping and cracking. Certain hardwoods like teak are renowned for their resistance to water absorption.

4. Maintenance Requirements

Regular oiling helps to keep the wood moist and stop drying out, thus quality hardwood boards should be easily maintained. Boards that require less frequent maintenance may be more appealing for everyday use.

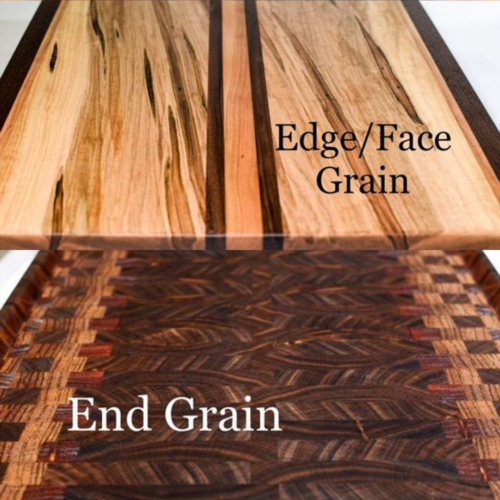

End Grain vs. Edge Grain Cutting Boards:

When choosing cutting boards, end grain or edge grain makes a big difference since each type has unique properties influencing longevity, maintenance, and performance. The two designs are thoroughly compared here:

End Grain Cutting Boards

Characteristics

Construction: Made from the ends of wood pieces bonded together, end grain cutting boards highlight the vertical fibers of the wood.

Knife-Friendly: The knife edge slips between the wood fibers instead of cutting through them, so preserving their sharpness longer and being softer on blades.

Self-Healing Properties: After use, cuts typically close up, therefore minimizing apparent damage and extending the lifetime of the board.

Microbial Resistance: End grain boards’ porous structure, which can trap bacteria away from the surface, helps them to be more successful in lowering bacterial translocation.

Pros

- Easy on knives results in less regular sharpening.

- Better in hiding over time wounds and scratches.

- Usually thought to be more visually appealing because of their distinctive patterns.

Cons

- Usually more costly since complicated manufacturing techniques.

- More prone to dry out and cracking under poor maintenance.

Edge Grain Cutting Boards

Characteristics

Construction: Made from strips of wood glued together with the edges facing up, creating a flat surface.

Harder on Knives: Unlike end grain boards, the knife directly slices through the fibers, therefore dulling blades more quickly.

Durability: Compared to end grain boards, they are less likely to warping and splitting even if they may display more cuts and scratches over time.

Pros

Usually more reasonably priced and readily available.

Easier to clean and maintain due to fewer seams and a smoother surface.

More resistant to moisture-related issues.

Cons

More likely to show obvious knife-related grooves and gashes.

Requires more regular care in terms of oiling and sanding to maintain the surface smoothness.

Summary Comparison Table:

| Feature | End Grain | Edge Grain |

| Knife Friendliness | Gentle on knives | Harder on knives |

| Self-Healing | Yes (cuts close up) | No (cuts remain visible) |

| Bacterial Resistance | Higher (traps microbes) | Lower (more exposed surface) |

| Cost | Generally higher | Generally lower |

| Durability | Can crack if not maintained | More resistant to warping |

| Maintenance | Requires careful upkeep | Easier to clean |

Factors to Consider When Choosing Wood:

Several elements should be taken into account while selecting wood for different uses such furniture, flooring, or cutting boards to guarantee longevity, practicality, and looks. The main elements to keep in mind are these:

1. Type of Wood

Hardwoods vs. Softwoods: Generally speaking, hardwoods—oak, maple, walnut—are more resistant to wear and durable than softwoods—pine and fir. High-use products like cutting boards are made of hardwoods because of their density and capacity to resist cuts without appreciable damage.

Specific Species: Different species has special qualities. For example, walnut gives a rich color and exceptional durability; maple is well-known for its toughness and moisture resistance. Natural antimicrobial qualities and water resistance are highlights of acacia.

Also read: 8 Reasons for Choosing Acacia Wood Cutting Boards

2. Heartwood vs. Sapwood

Heartwood: Usually denser and more resistant to rot and insect attack, heartwood is the inner core of the tree. Applications seeking for longevity and endurance could benefit from it.

Sapwood: The outer layer of the tree, sapwood is more susceptible to damage from moisture and pests. It is generally less durable than heartwood and should be avoided in applications where durability is critical.

3. Durability

Natural Resistance: Different timbers have different degrees of natural resistance against insects and deterioration. For instance, pine has less resiliency; oak heartwood is quite durable. Knowing the inherent lifetime of the wood species helps one to choose it for particular surroundings.

Treatment Options: Some woods can be treated to improve their resistance against moisture and pests. For example, pressure-treated wood may need particular maintenance to guarantee lifetime but can resist decay and insects.

4. Moisture Resistance

Different species of wood have varied absorption and release of moisture. Because they are less likely to warp or break, woods with less hygroscopic qualities are more suited for settings with changing humidity levels.

Regular treatment with oils or sealants helps preserve moisture resistance in hardwood objects like cutting boards, therefore extending their lifetime.

How to Maintain Your Wooden Cutting Board

Maintaining the lifetime, hygienic quality, and function in the kitchen of your wooden cutting board depends on you keeping it intact. This is a thorough instruction on properly caring for your wooden cutting board:

Daily Cleaning

Immediate Rinse: Rinse the board with warm water immediately following every usage to eliminate food particles. Steer clear of immersing it in water; warping and cracking might result with prolonged exposure.

Use Mild Soap: Using a soft sponge and a mild, fragrance-free dish soap, wash the surface. To avoid uneven drying and possible warping, scrub completely—including both sides of the board.

Dry Thoroughly: Straight away after cleaning, wipe the board dry with a fresh cloth. Store the board straight forward or in a well-ventilated area to guarantee total dryness and let air flow.

Sanitizing

Natural Solutions: Use an equal amounts vinegar and water or hydrogen peroxide solution for efficient sanitising. Spray or wipe this solution onto the surface; let it sit for a few minutes; then, rinse completely.

Baking Soda Paste: Making a paste from baking soda and water will help with tough stains or smells. Spoon this mixture onto the cutting board; then, rinse thoroughly.

Deep Cleaning (As Needed)

Salt and Lemon Treatment: Rub half a lemon dipped in salt over the board to remove severe smells and clean it. The lemon’s acidity helps sanitise; the salt functions as an abrasive.

Oiling and Conditioning

Regular Oil Application: Apply food-grade mineral oil or a specialised cutting board conditioner once a month or more frequently if used often to help the wood stay from drying out and cracking. Drizzle a tiny bit on the board and evenly distribute it; let it absorb for several hours or overnight before wiping off extra oil.

Avoid Certain Oils: Steer clear of some oils to prevent Use vegetable or olive oils for conditioning; they will go rancid and compromise the integrity of the wood.

Storage Tips

Proper Storage: Stacking things on top of your cutting board will help to avoid moisture accumulation that might cause mould growth. Store it hung to let air flow or straight forward in a cold, dry environment.

Maintenance Checks

Inspect Regularly: Look for major cuts, cracks, or wear-on-your cutting board marks. If you find major damage, you can sand off small scratches; but, if the wood is twisted or badly damaged, you might want to replace it to prevent bacterial contamination.

These maintenance guidelines will help you to guarantee that your wooden cutting board stays in great shape for years to come and offers a safe and efficient surface for food preparation.

Also read: Why Choose Olive Wood Cutting Boards ?

FAQs

1. How do I sanitize a wooden cutting board?

To kill bacteria, clean it with vinegar or a water and bleach combo.

2. Can I use the same cutting board for meat and vegetables?

Separate boards are best used to avoid cross-contamination.

3. How often should I oil my cutting board?

Aim once a month or anytime the wood seems dry.

4. What size cutting board should I buy?

Select a size that suits the workspace and meets your regular cutting requirements.

5. How long does a wooden cutting board last?

A good quality wooden cutting board can last decades with correct treatment.