Beveling of Glass

Introduction

Beveling of glass is a technique that elevates its aesthetic appeal, adding sophistication and depth to any space. Glass, with its transparent allure, has become a key element in modern architecture and interior design, seamlessly blending with various styles and materials. In this article, we explore the art of glass beveling, highlighting its significance, the process, and the many ways it can transform both homes and commercial spaces.

Glass, renowned for its clarity and reflective properties, has evolved beyond functional use into an artistic expression. Beveling, a technique that involves cutting and polishing the edges of glass at specific angles, imparts a distinctive visual effect.

Beveling of Glass: A Glimpse into History

Beveling dates back to the Middle Ages when it was used to embellish religious artifacts. Today, its legacy lives on, intertwining history with modern design.

The art of beveling, a technique that bestows elegance and sophistication upon glass and other materials, has a rich and intriguing history that spans centuries. Rooted in craftsmanship and innovation, the practice of beveling has evolved over time, leaving its mark on various cultures and industries. Let’s take a glimpse into the historical journey of beveling and explore its significance in shaping both artistry and functionality.

Early Beginnings:

The origins of beveling can be traced back to ancient civilizations. In antiquity, artisans and craftsmen began experimenting with techniques to refine the edges of glass and other materials. The earliest examples of beveled edges can be found in ancient Egyptian jewelry and decorative pieces, where slanted edges enhanced the aesthetics and durability of the artifacts.

Medieval and Renaissance Craftsmanship:

The art of beveling gained momentum during the medieval and Renaissance periods. Skilled artisans in Europe began employing beveled edges in stained glass windows, accentuating the play of light and creating intricate designs. These windows adorned cathedrals, churches, and important buildings, contributing to the visual splendor of religious and architectural structures.

Industrial Revolution and Modern Innovations:

The Industrial Revolution brought about significant advancements in glass production and processing techniques. With the advent of machinery, the process of creating beveled edges became more streamlined and efficient. Beveling machines were developed, enabling precise and consistent beveling, which was particularly beneficial for the production of furniture, mirrors, and decorative glass elements.

Decorative and Functional Significance:

Throughout history, beveling has held dual importance: decorative and functional. In furniture design, beveled glass became a hallmark of luxury and craftsmanship, adorning elegant pieces that graced palaces and affluent homes. The technique not only added visual appeal but also addressed safety concerns by eliminating sharp corners on glass surfaces.

Artistic Expression and Architecture:

As artistic expression evolved, beveling found its way into various art movements. Art Nouveau and Art Deco styles, for instance, embraced beveled glass for its ability to capture and reflect light in intricate and captivating ways. In architecture, beveled glass was used to embellish doors, windows, and skylights, contributing to the ornate aesthetics of buildings.

Contemporary Applications:

In the present day, beveling continues to thrive as a cherished technique in design and craftsmanship. It is employed in various applications, ranging from interior decor and furniture to artistic creations and architectural elements. The combination of traditional craftsmanship and modern technology allows artisans to explore new dimensions of creativity in beveling.

Preserving Tradition:

As technology advances, there is a growing appreciation for traditional craftsmanship. Artisans and enthusiasts continue to practice and celebrate the art of beveling, recognizing its historical significance and its enduring appeal in creating objects of beauty and utility.

The history of beveling is a testament to the ingenuity and artistic vision of cultures across time. From its origins in ancient Egypt to its integration into modern design, beveling has contributed to the evolution of art, architecture, and craftsmanship, leaving behind a legacy of sophistication and innovation.

Understanding Beveled Glass

Beveled glass refers to glass pieces where the edges are cut at an angle to create a sloping surface. This sloping surface, known as a bevel, reflects light in captivating ways, adding depth and dimension.

The Art of Beveling: How It’s Done

Beveling is achieved through a meticulous process. Skilled artisans employ cutting-edge machinery to precisely grind and polish the edges of glass to the desired angle. This precision enhances the refractive qualities of the glass, resulting in mesmerizing light play.

Beveling is a skilled technique that adds a refined edge and a touch of elegance to various objects, from glass and metal to wood and ceramics. This artful process involves creating a slanted surface or chamfer along the edge of a material, giving it a polished and aesthetically pleasing look. Whether you’re working on a DIY project or pursuing a professional endeavor, mastering the art of beveling can greatly enhance your craftsmanship. Let’s delve into the steps and methods involved in achieving this intricate design element.

Materials and Tools:

Before you embark on your beveling journey, gather the necessary materials and tools:

Workpiece: This could be anything from a glass sheet to a metal plate or a wooden board.

Safety Gear: Wear safety goggles, gloves, and a mask to protect yourself from potential debris.

Beveling Tools: Depending on the material you’re working with, you’ll need appropriate tools such as a beveling machine, a hand file, a router, or a chisel.

Measuring Tools: A ruler, calipers, or a protractor will help you accurately measure and mark the bevel angle.

Sandpaper and Polishing Compound: These are essential for refining and smoothing the beveled edge.

Steps to Create a Bevel:

Preparation:

Start by selecting the material and the appropriate beveling tool for your project.

Secure the workpiece firmly in place using clamps or a vice.

Marking the Bevel:

Determine the desired angle for the bevel. Common angles range from 15 to 45 degrees, depending on the effect you want to achieve.

Use measuring tools to mark the starting and ending points of the bevel along the edge of the material.

Beveling Process:

If you’re using a beveling machine, carefully guide the machine along the marked path, maintaining a steady motion and pressure.

For hand tools like files or chisels, start at one end of the marked path and work your way towards the other end. Use controlled, consistent strokes to create the beveled surface.

When using a router, choose a router bit with the desired angle and guide the router along the marked line.

Refining the Bevel:

After the initial bevel is created, switch to finer-grit sandpaper to smooth out any rough edges and imperfections.

Apply a polishing compound to a cloth and gently buff the beveled surface to achieve a glossy finish.

Cleaning and Final Touches:

Remove any dust or debris from the workpiece and the surrounding area.

Inspect the beveled edge for uniformity and smoothness. Make any necessary touch-ups.

Tips for Success:

Try doing your project on leftover materials first, before you start on your real project.

Maintain a consistent angle and pressure while beveling to ensure a uniform edge.

Keep your tools sharp and in good condition for optimal results.

Use appropriate safety gear at all times to prevent accidents.

Applications and Advantages

Let’s explore the various applications and advantages of glass beveling.

Applications:

Furniture Design: Glass beveling is commonly used in furniture design, especially for items like glass tabletops, mirrors, and glass cabinet doors. Beveled edges provide a luxurious touch and prevent sharp corners, making furniture both visually appealing and safer.

fabglassandmirror.com

Home Decor: Beveled glass panels can be incorporated into doors, windows, and room dividers to add a touch of elegance to interior spaces. They create beautiful light refractions and play with the surrounding light.

Decorative Mirrors: Beveled edges on mirrors create a unique framing effect, making the mirror itself a work of art. This technique is often used in vanity mirrors, wall mirrors, and decorative mirrors.

Art and Craft: Glass beveling finds its place in the realm of art and craft projects. It allows artists to experiment with light, reflections, and textures, resulting in stunning visual effects.

Architectural Elements: In architecture, beveled glass is utilized in doors, windows, and even in skylights. The beveled edges contribute to the overall design aesthetics of the building.

Retail Displays: Retail spaces often employ beveled glass for display cases and shelving. The polished edges create an upscale look and draw attention to the items on display.

Advantages:

Enhanced Aesthetics: The primary advantage of glass beveling is its ability to elevate the appearance of glass objects. The slanted, polished edges catch and refract light, adding depth and sophistication to the glass.

Safety: Beveled edges are less likely to cause injuries compared to sharp, untreated edges. This is especially important for furniture and home accessories that people may come into contact with.

Light Manipulation: Beveled glass edges interact with light in fascinating ways. They create prismatic effects by breaking light into its spectral colors, enhancing the play of light within a space.

Customization: Glass beveling allows for a high degree of customization. You can choose the width of the bevel, the angle, and even the overall design. This versatility makes it a valuable tool for designers and architects.

Durability: Despite the intricate detailing, beveled edges can actually enhance the structural integrity of glass. By removing the vulnerable sharp edges, the glass is less likely to chip or crack.

Value Addition: Glass items with beveled edges often command higher value in the market due to the craftsmanship and aesthetic appeal they offer.

Timeless Elegance: The timeless beauty of beveled glass ensures that it remains a sought-after choice for various applications, from classic to contemporary designs.

Glass beveling is a fusion of artistry and functionality, offering a wide range of applications and advantages. Whether you’re designing furniture, home decor, or architectural elements, incorporating beveled glass edges can significantly enhance the overall appeal and value of your creations.

Choosing the Right Beveled Glass

Selecting the appropriate beveled glass for your project is a crucial decision that influences both the aesthetics and functionality of the end result. Beveled glass comes in various styles, thicknesses, and finishes, making it essential to consider your project’s requirements and desired visual impact. Here’s a comprehensive guide to help you make an informed choice when choosing the right beveled glass.

Considerations When Choosing Beveled Glass:

Project Type:

Determine the purpose of the glass. Is it for furniture, home decor, architectural elements, or art installations? Different projects may require specific types of beveled glass.

Style and Aesthetics:

Beveled glass is available in a range of bevel widths, angles, and patterns. Consider the overall design style and the level of detail you desire in your project.

Application:

Will the glass be exposed to high traffic? Is it for decorative purposes or functional use? Understanding the glass’s intended application helps determine the required thickness and durability.

Location:

Consider whether the glass will be used indoors or outdoors. Outdoor applications may require glass that is more resistant to weather and environmental factors.

Light Play and Reflection:

Think about how you want the glass to interact with light. Different bevel angles and patterns create varying light refractions and reflections.

Size and Dimensions:

Measure the dimensions accurately to ensure you order the correct size of beveled glass. Custom sizing may be necessary for certain projects.

Compatibility with Other Materials:

If the beveled glass will be combined with other materials (e.g., wood, metal), consider how they will interact and complement each other.

Budget:

Set a budget for your project, and explore beveled glass options within that range. Keep in mind that more intricate bevel patterns and larger sizes might be more expensive.

Types of Beveled Glass:

Clear Beveled Glass:

Classic and versatile, clear beveled glass enhances light play and provides a timeless aesthetic.

Textured Beveled Glass:

Textured surfaces combined with beveled edges can add depth and complexity to the glass, creating unique visual effects.

Colored Beveled Glass:

Adding color to beveled glass can create a stunning focal point or match the color scheme of your project.

Patterned Beveled Glass:

These glasses incorporate intricate patterns along with beveled edges, adding an extra layer of visual interest.

Custom Beveled Glass:

If your project demands a specific design or size, custom beveled glass can be created to match your exact specifications.

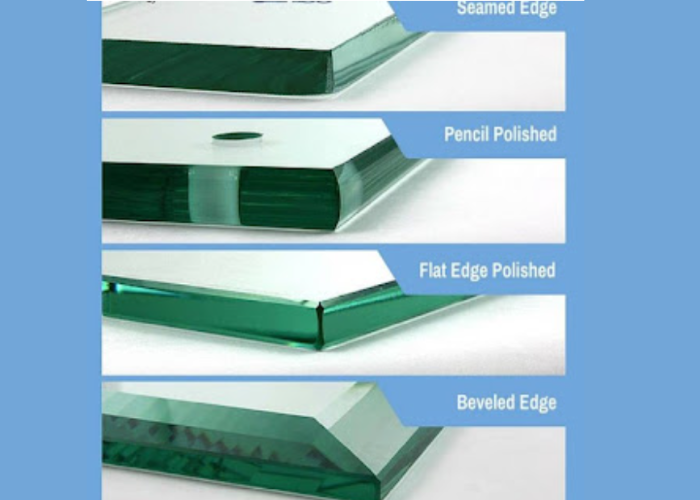

Finishes:

Polished Finish:

A high-gloss, shiny surface that enhances light reflection and creates a sophisticated look.

Satin Finish:

A matte, frosted appearance that diffuses light and offers a softer, more subdued effect.

Antique Finish:

A weathered or aged look that adds character and vintage charm to the glass.

Choosing the right beveled glass involves a balance between design preferences, functionality, and the specific requirements of your project. By carefully considering the factors mentioned above, you can ensure that the chosen beveled glass enhances the beauty and functionality of your creation.

Maintenance and Care

Caring for beveled glass involves gentle cleaning and avoiding abrasive materials. Regular maintenance ensures the glass retains its brilliance over time.

DIY Beveling: Is It Feasible?

While DIY projects have gained popularity, beveling glass requires specialized tools and expertise. Entrusting professionals guarantees impeccable results.

Beveling vs. Etching: Decoding the Difference

Beveling and etching are two distinct techniques used to enhance the appearance and design of glass and other materials. While they both contribute to the visual appeal of the finished product, they involve different processes and achieve different effects. Let’s delve into the details of beveling and etching to decipher the key differences between these artistic methods.

Beveling:

Definition: Beveling is the process of creating a slanted, polished edge on the material, usually glass, by removing a small portion of the edge at a specific angle.

Process:

Beveling involves using specialized tools to cut and shape the edge of the material.

The result is a smooth, angled edge that adds elegance and depth to the piece.

Beveled edges catch and refract light, creating a prism-like effect that enhances the visual interest.

Effects:

Beveling emphasizes the beauty of the material’s edge, making it more aesthetically pleasing.

It adds a touch of luxury and sophistication to glass, mirrors, and other surfaces.

Beveled edges are used to make corners less sharp and safer, especially on things like glass furniture.

Applications:

Furniture design: Glass tabletops, mirrors, and cabinet doors.

Home decor: Glass doors, windows, and decorative glass panels.

Architecture: Glass elements in doors, windows, and skylights.

Art and craft: Creating unique light-refracting effects in glass projects.

Etching:

Definition: Etching is the process of using chemicals, abrasives, or mechanical tools to create designs, patterns, or images on the surface of glass or other materials.

Process:

Etching involves applying an etching solution or abrasive material to the surface of the material.

The solution or abrasive reacts with the material, creating a frosted or textured appearance.

Stencils or masks can be used to create intricate designs during the etching process.

Effects:

Etching adds texture and visual interest to the surface of the material.

It can create intricate, detailed designs that are permanently etched into the glass.

Etched surfaces may diffuse light, resulting in a soft, diffused glow.

Applications:

Decorative glassware: Etched patterns on glass cups, vases, and bowls.

Art and design: Creating detailed and personalized glass art pieces.

Privacy glass: Etching can be used to partially obscure glass for privacy while maintaining light transmission.

Key Differences:

Process:

Beveling involves shaping and polishing the edge of the material.

Etching involves altering the surface of the material to create designs or patterns.

Effects:

Beveling enhances the edge and light-refracting properties of the material.

Etching adds texture and decorative patterns to the surface.

Tools:

Beveling requires tools for cutting and shaping edges.

Etching involves chemicals, abrasives, or mechanical tools for surface alteration.

Outcome:

Beveling creates a polished, angled edge.

Etching creates textured or frosted designs on the surface.

While both beveling and etching contribute to the beauty of glass and other materials, they differ in their processes, effects, and applications. Beveling focuses on edge refinement and light play, while etching adds decorative patterns and texture to the surface.

Choosing between these techniques depends on the desired artistic outcome and the intended use of the finished piece.

Cost Considerations

The cost of beveled glass varies based on factors like size, complexity, and thickness. It’s an investment in both artistry and aesthetics.

Glass beveling, a captivating technique that enhances the visual appeal of glass objects, involves both craftsmanship and specialized equipment. When considering glass beveling for your project, it’s essential to understand the cost factors that come into play. From materials and labor to equipment and customization, several elements influence the overall cost of incorporating beveled glass into your design.

Materials:

Glass Type: The cost of the glass itself varies based on factors like thickness, clarity, and any special features (such as tempered or colored glass).

Beveling Tools: Quality tools are necessary for precise beveling, and their cost can range depending on the complexity of the project.

Labor and Skill:

Skilled Labor: The expertise of the craftspeople involved in the beveling process contributes to labor costs. Highly intricate designs or custom projects might require more skilled labor.

Time: The complexity of the design and the size of the glass piece influence the time required for beveling, which can impact labor costs.

Design Complexity:

Bevel Width and Depth: More intricate and wider bevels might require additional time and precision, affecting the cost.

Custom Designs: Custom patterns or designs might involve more manual work, leading to higher costs compared to standard designs.

Equipment and Tools:

Beveling Machinery: The cost of using or renting beveling machines and tools for the process can contribute significantly to the overall expenses.

Maintenance: Regular maintenance of equipment ensures quality results but also adds to the operational costs.

Size of the Glass Piece:

Larger Pieces: Beveling larger glass pieces requires more time, effort, and potentially larger machinery, leading to higher costs.

Quantity:

Bulk Orders: If you’re ordering multiple pieces with the same design, there might be potential for volume discounts.

Customization:

Personalized Designs: If you’re opting for unique, customized designs, the extra time and effort put into creating the design can influence costs.

Additional Treatments:

Finishing: Polishing, edge treatments, or additional detailing might incur additional costs but can enhance the final result.

Shipping and Handling:

Packaging: Proper packaging to ensure the safe delivery of beveled glass might lead to additional shipping and handling costs.

Location and Vendor:

Geographical Location: The cost of labor, materials, and services can vary based on the location of the beveling service provider.

Vendor Reputation: Established and reputable vendors might charge higher prices due to their expertise and quality standards.

Project Type:

Commercial vs. Residential: Commercial projects might have different pricing structures compared to residential projects due to scale and scope differences.

Budgeting and Planning:

Setting a Budget: Defining a budget for your project helps you align your expectations with the available resources.

Comparing Quotes: Getting quotes from different service providers allows you to compare costs and make an informed decision.

The cost of glass beveling varies based on multiple factors, including materials, labor, design complexity, equipment, and customization. By understanding these considerations and planning accordingly, you can achieve stunning beveled glass designs that align with your project’s vision and budget.

Finding Expert Beveling Services

To achieve the best results, partnering with skilled artisans and reputable glassworks is essential. Their expertise ensures the creation of stunning beveled pieces.

Innovations in Beveled Glass

Contemporary artists and designers continually push the boundaries of beveling, experimenting with shapes, angles, and textures to create innovative and striking glass installations.

Conclusion

Beveling transforms glass from a mere material into a work of art that captures light, shadow, and imagination. Its ability to enhance spaces and evoke emotions makes it a timeless technique in the world of design.

FAQs (Frequently Asked Questions)

1. Can beveled glass be used in outdoor applications?

Yes, beveled glass can be used outdoors, but it’s important to choose suitable glass thickness and quality for durability.

2. Is beveling only done on clear glass?

No, beveling can be done on various types of glass, including tinted and frosted glass.

3. Can I repair chipped beveled edges myself?

Repairing beveled edges requires professional expertise to maintain the glass’s integrity.

4. Are there limitations to beveling angles?

While there are common angles, custom angles can also be created to suit specific design preferences.

5. Can beveled glass pieces be custom-made?

Absolutely, many glassworks offer customization options for beveled glass pieces to align with your vision.

Also read: What Is Sheesham Wood?