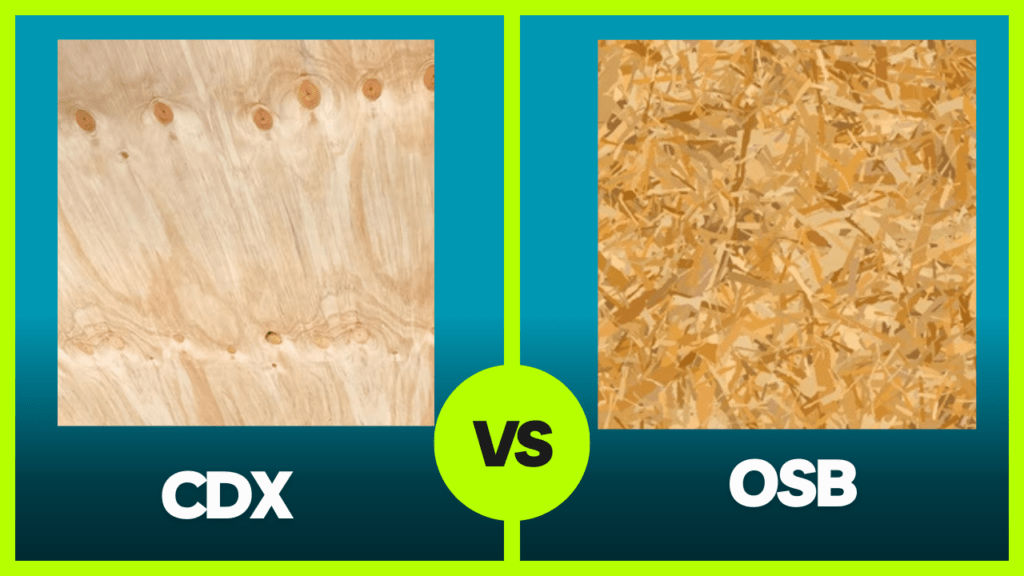

CDX vs. OSB – When it comes to construction projects, whether it’s your family home or a barn to house livestock, your sheathing or subfloor material can really be one of the deciding factors in whether generations will harvest memories under that structure. CDX Plywood vs. OSB – Which Is The Better from two of the most popular contrast categories.

Both are engineered wood products that offer better resistance to moisture, insects, mildew and rot than solid wood—they’re used in both houses and light commercial construction as a more durable alternative to plywood and multilayered particleboard. But they have different strengths, weaknesses and price points.

If you’re not sure whether CDX or OSB will be better suited for your project, then this in-depth comparison guide will cover everything you need to know about CDX vs OSB: from construction, price, and how long it lasts to water resistance and best uses.

What is CDX Plywood?

CDX plywood is a type of veneer plywood where thin layers (veneers) of wood are glued and pressed together.

- The “C” represents the grade of the face veneer (medium quality).

- The “D” refers to the back veneer grade (lower quality).

- The “X” stands for “exposure,” meaning this plywood can handle limited moisture exposure.

CDX plywood isn’t waterproof but is moisture resistant as it’s made with water-resistant adhesives. That makes it a solid material choice for exterior sheathing, subflooring, roof decking and even concrete formwork (as long as the wood won’t remain exposed to water for lengthy periods).

What is OSB (Oriented Strand Board)?

OSB is an engineered wood product made from strands or chips of wood arranged in layers, glued with resins, and pressed under high heat and pressure. Its cross-oriented structure gives it impressive strength and uniformity.

Key features of OSB include:

- Made from smaller, fast-growing trees → more sustainable and eco-friendly.

- Comes in large panels, good for modern architecture.

- Frequently cheaper than any grade of plywood, such as CDX.

OSB is popular for roof sheathing, wall sheathing, and subflooring, especially where cost savings are important.

CDX vs OSB: Side-by-Side Comparison

| Feature | CDX Plywood | OSB |

| Material | Veneer layers glued together | Strands/chips glued and pressed |

| Moisture Resistance | Handles limited moisture, dries faster | More moisture resistant, but slower to dry once wet |

| Durability | Strong, reliable, good recovery from swelling | Strong, consistent, but edges prone to swelling |

| Workability | Easier to cut, nail, screw, and paint | Harder to cut or fasten cleanly |

| Surface Finish | Smooth, sanded, better for finishing | Rougher surface, not ideal for paint/finish |

| Panel Size/Availability | Smaller sizes, easier to handle | Large panels, heavier |

| Cost | More expensive | Cheaper |

| Weight | Lighter | Heavier |

Moisture Resistance: Which Performs Better?

One of the questions we get asked is about CDX and OSB how each handles moisture.

- OSB’s resin content also gives it increased moisture resistance, and this makes it an ideal option in damp areas. But if it gets wet, it sucks water and expands, making it difficult to cure, even leading to a distortion of edge.

- CDX, in contrast, takes up more water but dries out faster and bounces back closer to its original state. This also makes it a feasible selection for regions that will be subject to transient moisture exposure.

For tropical or rainy climates, OSB may resist moisture better initially, but CDX has the advantage of quicker recovery once wet.

Strength and Durability

Both CDX and OSB are solid, structural materials, with slightly different performances:

- CDX: Strong and rigid with. Frequently used in subfloors, platform roofs and walls where functional load bearing is important.

- OSB: Provides uniform strength for the entire panel because it has no natural defects like knots. Great for structural sheathing and decking.

If strength under concentrated loads is a priority, CDX has the edge. If uniformity across a large surface matters, OSB is reliable.

Ease of Use and Workability

For builders and DIYers, ease of handling is important:

- CDX plywood cuts easily, and studies proved it takes nails and screws well. Its relatively smooth surface also makes it ideal for finishing or appearance applications.

- OSB is denser and heavier, which can make cutting and fastening more difficult. Its rough texture also makes painting or polishing a challenge.

If you’re looking for convenience and a polished finish, CDX is more user-friendly.

Cost Considerations

Construction is often about budget.

- OSB is cheaper than CDX plywood, so it is mostly used in big construction projects such as roofing or wall sheathing when lots of water-resistant panels are needed.

- CDX is more expensive, but it generally provides better workability, finish and faster dry times when damp.

For cost-sensitive projects OSB is a good choice. CDX tends to be more expensive, but for the long-term longevity and a nice look, it might just be worth it.

Best Applications for CDX

- Roof decking (when covered with shingles or membranes)

- Subfloors under tile, carpet, or hardwood

- Concrete formwork (smooth surface is a plus)

- Exterior wall sheathing in moderate humidity zones

Best Applications for OSB

- Roof sheathing (especially large spans)

- Wall sheathing in cost-sensitive builds

- Subflooring in dry to moderately humid environments

- Decking substrate (if sealed at the edges)

Which One Should You Choose?

The choice between CDX vs OSB ultimately depends on your project’s priorities:

- Choose CDX plywood if:

- You need easier workability and finishing.

- Moisture exposure will be temporary.

- A smoother, polished surface is required.

- Choose OSB if:

- Cost is the primary concern.

- You need larger, uniform panels.

- The structure will be in a humid area but protected from standing water.

For most budget builds, OSB is practical. For premium or long-lasting projects, CDX often wins.

FAQs About CDX vs OSB

1. Is CDX better than OSB?

CDX is stronger under concentrated loads, easier to work with, and offers a smoother finish. OSB is less expensive and more resistant to moisture, but harder to cut and finish.

2. Why is OSB cheaper than CDX?

OSB is made from small, fast-growing trees so it’s a more economical board to create.

3. Can CDX or OSB be used outdoors?

Yes, but neither should be left exposed permanently. Both require some form of protection (whether shingles, siding, membranes or sealants).

4. Which lasts longer, OSB or CDX?

Both last for decades, when properly installed and protected. However, CDX has a better tendency to return to its original condition after exposure to water but OSB initially resists water penetration.

Conclusion

When it comes to CDX vs OSB, there’s no one-size-fits-all answer. Both are excellent building materials with proven track records in the construction industry.

- OSB is the go-to choice for cost-conscious projects needing large, uniform, moisture-resistant panels.

- CDX is better where strength, workability, and surface quality matter most.

By considering your budget, climate, and intended use, you can make the right choice and ensure your project’s durability and performance for years to come.