If you ask the common folk about “wood decay,” most will assume that it’s a bad thing. Something weak. Something useless.

But in the world of woodworking there is one gorgeous exception: spalted maple.

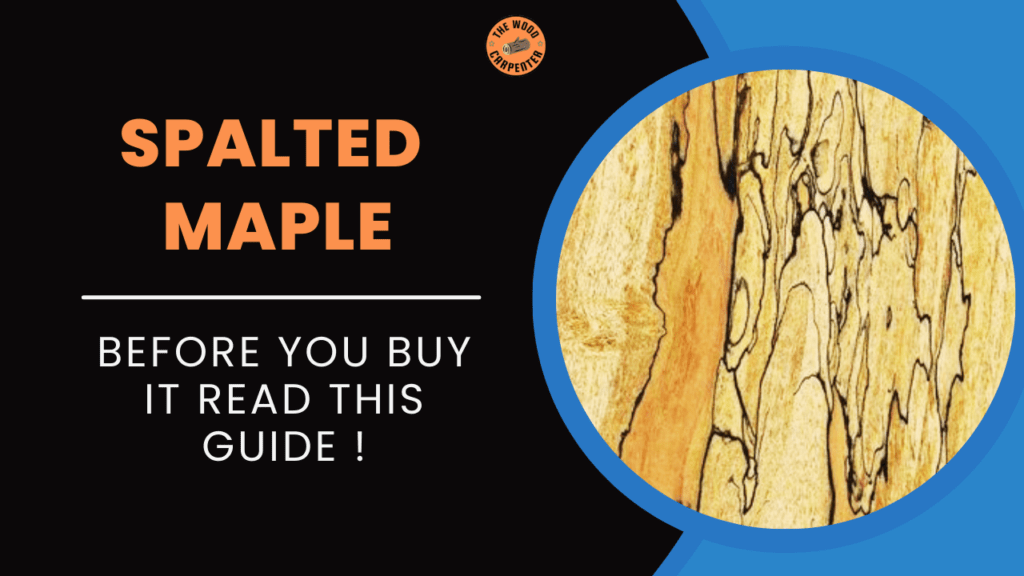

Spalted maple is evidence that nature can turn decay into art. What appears to damage at first is actually one of the most stunning woods you could ever dream of working with. Odd lines and delicate color shifts combined to make wood that looks hand-painted by nature.

This guide will cover everything you need to know about spalted maple.

What Makes Spalted Maple So Special?

Spalted maple is not a special variety of maple tree.

It begins as regular maple wood.

What makes it different is what happens later.

Spalting happens when certain fungi begin to grow inside the wood after the tree is cut or starts to die. These fungi slowly feed on the wood. As different fungi grow and fight for space, they create dark boundary lines called zone lines.

These lines are the black or dark brown streaks people love so much.

Think of it like this:

Tiny fungi are fighting tiny wars inside the wood. Where they meet, dark lines appear. These lines do not follow straight paths or patterns. They twist, curve, and spread in natural ways.

That is why no two pieces of spalted maple ever look the same.

Maple is the most popular wood for spalting because its light color makes those dark lines stand out clearly.

The Science Behind Spalting (Simple Explanation)

Spalting starts when fungi break down parts of the wood called cellulose and hemicellulose. This happens slowly and in stages.

During early spalting, you may see:

- Dark zone lines

- Light tan, gray, or brown color changes

- Soft shading across the surface

For woodworkers, timing is everything.

If the wood is dried at the right moment, the fungi stop growing and the patterns are locked in place.

If you wait too long, the wood becomes too soft and weak to use.

If you stop too early, the patterns may look dull or incomplete.

Good spalted maple is wood that was stopped right in the middle of decay.

Spalted Maple vs Ambrosia Maple

Many beginners mix these two up, but they are not the same.

Spalted maple is caused by fungi.

Ambrosia maple is caused by beetles.

Ambrosia beetles drill tiny tunnels into living trees. They carry fungi with them, which stains the wood around those tunnels.

Here’s the key difference:

- Spalted maple has flowing dark lines and patches

- Ambrosia maple has small holes with stained trails around them

Both are beautiful, but they come from very different natural processes.

Why Woodworkers Love Spalted Maple

Spalted maple is not just pretty. It is also very useful.

Woodworkers love it because:

- It looks amazing

The patterns add instant character to furniture, bowls, art pieces, and tables. - It works well when dried properly

Good spalted maple cuts, sands, and finishes nicely. - Every piece is unique

You can never duplicate the same look twice. - It is lighter than many hardwoods

This makes it easier to move, cut, and shape.

You’ll often see spalted maple used in furniture, cabinets, wall art, musical instruments, live edge slabs, and epoxy river tables.

Working With Spalted Maple: What to Know

Spalted maple is beautiful, but it needs extra care.

Inspecting the Wood

Not all spalted maple is good wood.

Some areas may be strong, while others may be too soft. Always check before using it.

A simple test is the fingernail test. Press your fingernail into the spalted area:

- If it dents deeply or crumbles, that area is too weak

- If it feels firm, it’s usable

Good spalted maple should still feel solid, even if it is a little softer than normal maple.

Common Problems and Easy Fixes

Spalted maple can come with a few issues.

- Very soft or “punky” areas

These feel weak and crumbly. Cut them out completely. - Dark dusty pockets

These can smear during sanding. Use thin CA glue to lock them in place before sanding. - Small empty gaps or cracks

Fill them with epoxy mixed with black pigment so it blends with the natural lines.

Sanding Spalted Maple the Right Way

Sanding spalted maple takes patience.

Always sand with the grain, not against it.

Start with rough sandpaper and slowly move to finer grits.

Be gentle around heavy spalting. If you sand too hard, you can remove the very patterns you want to show off.

The goal is smooth wood, not flat lifeless wood.

Finishing Spalted Maple for the Best Look

A good finish makes spalted maple come alive.

Best Finishing Tips

- Start with clean, smooth wood

- Choose finishes that highlight grain, not hide it

- Apply thin coats instead of one thick coat

- Let each coat dry fully

- Test on scrap wood first if possible

Many woodworkers love hardwax oils like Osmo Oil. Tung oil, linseed oil, lacquer, varnish, and polyurethane also work well, depending on how much protection you need.

For tabletops or heavy-use items, stronger finishes give better long-term protection.

Other Woods That Can Spalt

Maple is the most popular, but it’s not the only wood that can spalt.

Other woods that spalt well include beech, birch, poplar, sycamore, and hackberry. Some tropical woods like mango and tamarind can spalt too.

Maple remains the favorite because its light color creates the strongest contrast with dark zone lines.

Where to Find Good Spalted Maple

Spalted maple is not always easy to find.

Big lumber yards often avoid it because it varies so much. Small sawmills and specialty wood dealers are better places to look.

Live edge slab sellers often carry spalted maple because the patterns look stunning with natural edges.

If possible, always inspect spalted maple in person. Photos don’t always show soft spots or hidden flaws.

Health and Safety Tips

Spalted wood contains fungal spores.

When cutting or sanding:

- Work in a ventilated area

- Wear a good dust mask or respirator

- Clean up dust often

If you notice breathing issues or irritation, take extra precautions or stop working with it.

The Story Behind Every Spalted Maple Project

Every piece of spalted maple tells a story.

It started as a living tree.

Nature began breaking it down.

You stepped in at the right moment and saved its beauty.

Working with spalted maple is a partnership between nature and craft. The fungi created the art. You turn it into something useful, lasting, and meaningful.

That’s what makes spalted maple so special.

Frequently Asked Questions About Spalted Maple

Is spalted maple as strong as normal maple?

It depends. Light spalting keeps good strength. Heavy decay makes it weaker. Always test before using it for load-bearing parts.

Can I make spalted maple myself?

Yes, but it’s very hard to control. It can take months or years, and timing is tricky. Most people prefer to buy it.

How do I stop it from decaying more?

Dry it properly. Once moisture is low, fungi die and the process stops.

What’s the difference between hard and soft spalted maple?

Hard maple is denser and stronger. Soft maple is easier to work but less durable.

Why are some lines darker than others?

Different fungi create different colors. Moisture and time also affect darkness.

Is spalted maple safe for cutting boards?

It’s not recommended. Soft spots and food safety concerns make it better for non-food projects.

Do I need special glue?

No. Regular wood glue works. Epoxy is best for soft areas.

How should I store it?

Keep it dry, flat, and well-ventilated, just like other hardwoods.

Final Thoughts

Spalted maple is one of nature’s prettiest surprises. Decay starts to turn into design. What some others throw away becomes a centerpiece.

Yes, it needs more care. Yes, it takes more patience.

But the reward is wood that looks alive, artistic, and impossible to copy.

When you work with spalted maple, you’re not just making something.

You’re capturing a moment in nature — and making it something extraordinary.