Zebrawood, or Zebrano, is a rare type of strong wood that people really like because it looks so different. Here’s a detailed look at Zebrawood, including what it’s like, how it’s used, how easy it is to work with, and how it helps the environment.

Zebrawood

Striped wood from several tree species

Definition

Zebrawood is a term for the wood from several tree species, known for its distinctive striped appearance resembling a zebra.

Historical Origin

The term ‘zebrawood’ was first recorded in 1773 with imports noted from the Mosquito Coast.

Primary Species

Originally referred to wood from Astronium graveolens, but later primarily from Microberlinia brazzavillensis (zebrano).

Characteristics of Zebrawood

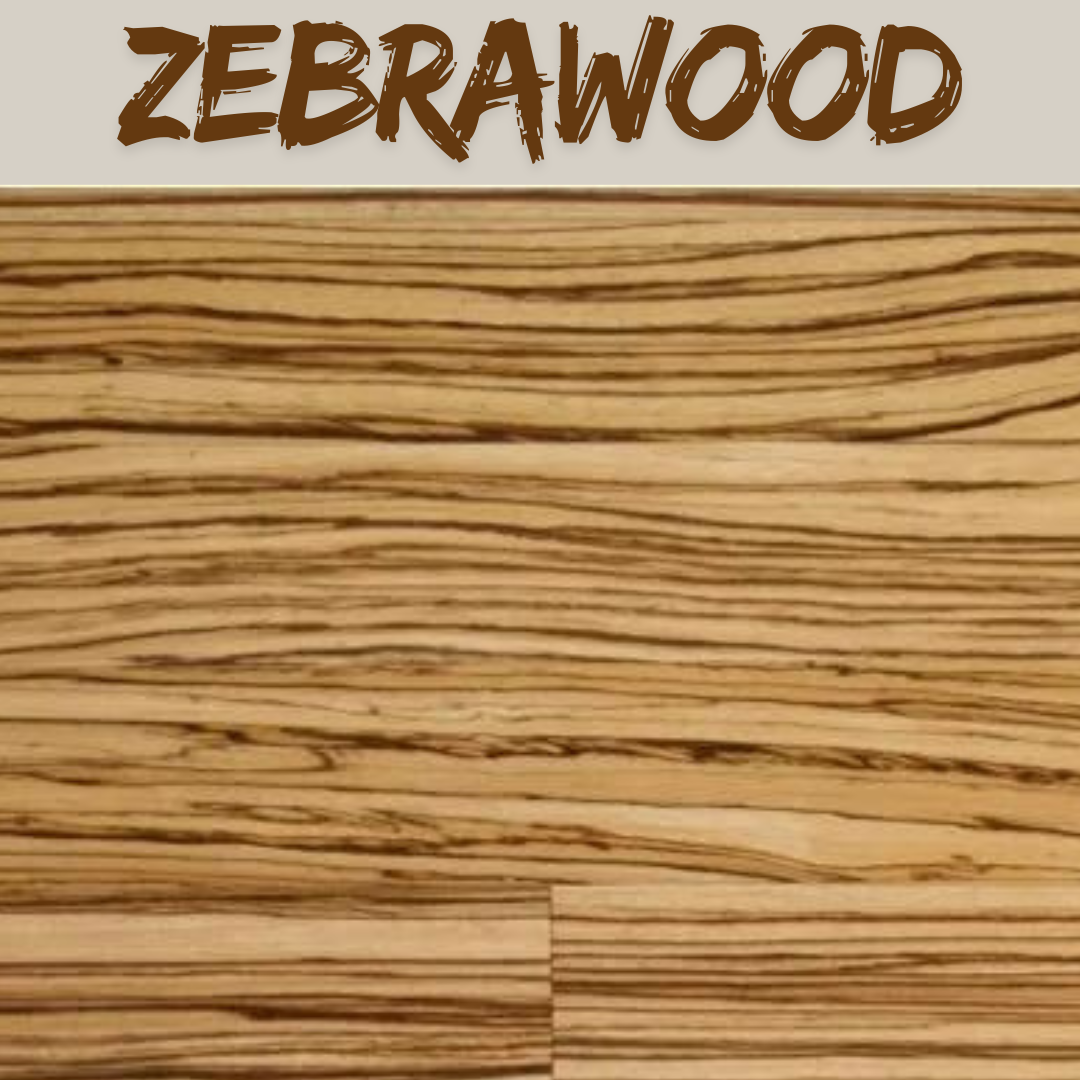

Appearance

Zebrawood is famous for its eye-catching appearance, which features a light golden-yellow to pale brown background adorned with dark brown to black streaks. These stripes look like the markings on a zebra. The pattern varies depending on how the wood is cut. Quartersawn Zebrawood has more consistent stripes, while flatsawn Zebrawood displays wavy and irregular patterns.

Grain and Texture

Zebrawood has a rough texture with big pores and a grain that’s interlocked or wavy. This grain pattern can make working with the wood difficult because it tends to tear out when you plane or smooth it.

Durability

This Wood is a tough and dense hardwood, rated 1575 on the Janka hardness scale, which means it’s more durable than many popular hardwoods such as oak. It’s also resistant to insects and decay, so it works well for both indoor and outdoor projects.

Odor and Allergies

When you work with this wood, it gives off a distinctive smell that some people find unpleasant. It’s also known to be a sensitizer, which means it can irritate your eyes and skin, and if you’re not careful, it might cause breathing problems too.

Uses

Zebrawood’s unique appearance and durability make it suitable for a variety of applications, including:

Furniture: High-end furniture pieces often use this wood for its aesthetic appeal.

Flooring: Its hardness and durability make it an excellent choice for flooring.

Decorative Items: Commonly used for knife handles, platters, and luxury items like watches and sunglasses.

Musical Instruments: Frequently used for guitar backs and other components due to its visual and acoustic properties.

Veneers: Often used in veneers for its striking appearance.

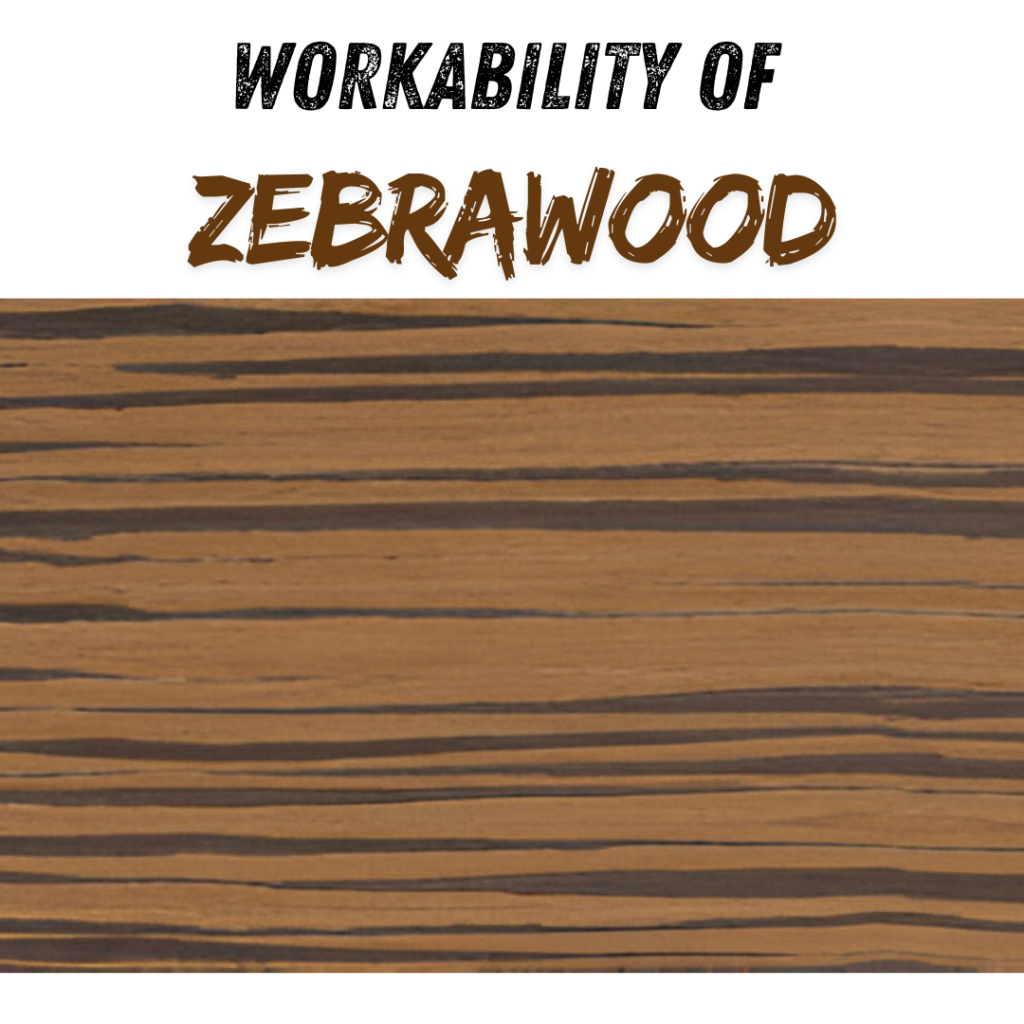

Workability

Zebrawood, also known as Zebrano, is a beautiful and durable hardwood, but it presents several challenges when it comes to workability. Here is a detailed overview:

Machining and Cutting

Sawing: Zebrawood can be sawn easily using both hand and power tools. However, its interlocking grain can cause tear-out when planing or surfacing.

Planing: Planing Zebrawood is tricky due to its interlocked grain, often resulting in tear-out. Using sharp tools and making light passes can help minimize this issue. Alternatively, using a drum sander or planing at an angle can also reduce tear-out.

Laser Engraving and Cutting: Zebrawood is suitable for laser engraving and cutting, making it ideal for detailed and decorative projects.

Finishing:

Zebrawood, known for its bold appearance and rough texture, can be finished with various products to bring out its natural beauty and protect the wood. Here are some recommended finishes:

Conversion Varnish

Conversion varnish is highly recommended for this wood, especially for furniture and cabinetry. It offers a clear, durable finish that highlights the wood’s grain and color. Users often find that multiple coats, such as MLC’s Krystal conversion varnish, are needed for a smooth surface due to the wood’s open grain.

Polyurethane

Both oil-based and water-based polyurethane are great choices for finishing Zebrawood. Oil-based polyurethane adds a warm, amber tint that enhances the contrast between the light and dark stripes. Water-based polyurethane provides a clear finish that maintains the wood’s natural color and is known for its durability and easy application.

Tung Oil and Danish Oil

Tung oil and Danish oil are popular for those preferring an oil finish. These oils penetrate the wood to enhance the grain while providing a natural appearance. Tung oil can be applied in multiple thin layers to build protection, while Danish oil, a blend of oil and varnish, offers both a natural look and varnish-like protection.

Hard Wax Oils

Hard wax oils, like Osmo, are ideal for durable finishes on items such as game boards. They are easy to apply and create a tough surface that enhances the wood’s natural beauty.

Lacquer

Lacquer, including catalyzed lacquer, is effective for Zebrawood. It dries quickly and can be layered to achieve a glossy or satin finish. Spray-can lacquer is convenient for smaller projects.

These finishes not only protect Zebrawood but also enhance its unique aesthetic, making it suitable for a variety of woodworking projects.

Also read: Why Choose Cocobolo Wood ? Discover Its Natural Charm

Prepping Tips for Finishing Zebrawood

Pore Filling:

Zebrawood has large open pores that are difficult to fill. Using a transparent pore filler like Behlen Por-O-Pak or Crystalac before applying the final finish helps in achieving a smooth surface.

Sanding:

Sanding between coats is crucial for a smooth finish. Start with a coarse grit to level the surface and progress to finer grits. A sanding sealer can also fill pores and create a smooth base for the final finish.

Multiple Coats:

Because of its open grain, Zebrawood often needs several coats of finish to achieve an even surface. Allow each coat to dry completely before sanding and applying the next coat. This process ensures a high-quality finish that enhances the natural beauty of Zebrawood.

Challenges and Precautions

Odor:

Zebrawood emits a strong and unpleasant smell when it’s being worked, especially in enclosed spaces. To reduce discomfort, it’s important to have good ventilation and wear protective gear like respirators.

Splinters:

This wood can produce large and sharp splinters, so handling it carefully during work is crucial to avoid injury.

Tool Wear:

The coarse grain structure of Zebrawood can dull tools quickly. It’s recommended to use carbide-tipped tools or sharpen your tools frequently to maintain efficiency.

Allergies/Toxicity:

Zebrawood is known to cause allergies and can irritate the eyes, skin, and respiratory system. To minimize exposure to wood dust, wear protective gear such as gloves, masks, and eye protection when working with Zebrawood. Taking these precautions ensures a safer and more comfortable woodworking experience with this beautiful hardwood.

Best Practices

Sharp Tools:

Always use sharp tools to reduce the risk of tear-out and achieve cleaner cuts when working with Zebrawood.

Light Passes:

Take light passes when planing or surfacing Zebrawood to minimize the chances of tear-out and achieve smoother results.

Protective Gear:

Wear appropriate protective gear to shield yourself from the strong odor and potential allergic reactions associated with Zebrawood.

Pre-drilling:

When fastening Zebrawood, especially near the ends of boards, it’s advisable to pre-drill holes to prevent splitting and ensure secure attachments. These precautions help maintain the integrity of the wood and enhance the quality of your woodworking projects.

Conclusion

Zebrawood is a beautiful and strong type of hardwood that adds a unique look to many woodworking projects. It’s used for making high-quality furniture, floors, decorations, and musical instruments.

Although it can be tricky to work with, its special appearance and strong qualities make it very popular. It’s important to get Zebrawood from sources that responsibly manage forests to protect this valuable wood for the future.

Also read: Poplar Wood 101: Detailed Insights and Practical Uses for DIYers

Understanding Sapele Wood: Pros and Cons Explained

FAQ

Is Zebrawood Real Wood?

Yes, Zebrawood is a genuine type of wood. It comes from various tree species, with Microberlinia brazzavillensis being the most well-known. These trees are found in Central Africa, especially in countries such as Gabon, Cameroon, and Congo. It is famous for its striped look, resembling the stripes of a zebra, which is how it got its name.

Is Zebrano Wood Expensive?

This wood is often costly, though it’s usually not as pricey as other exotic woods like Ebony or Rosewood. The cost can differ based on the wood’s quality and size, but overall, it’s considered a premium wood due to its distinct appearance and limited supply.

Is Zebrawood Rare?

This wood is categorized as vulnerable because its population has significantly declined, mainly due to habitat loss. While it’s not listed in the CITES Appendices, it is included in the IUCN Red List of Threatened Species. Its scarcity, along with its distinctive appearance, contributes to its higher cost and popularity in the woodworking industry.