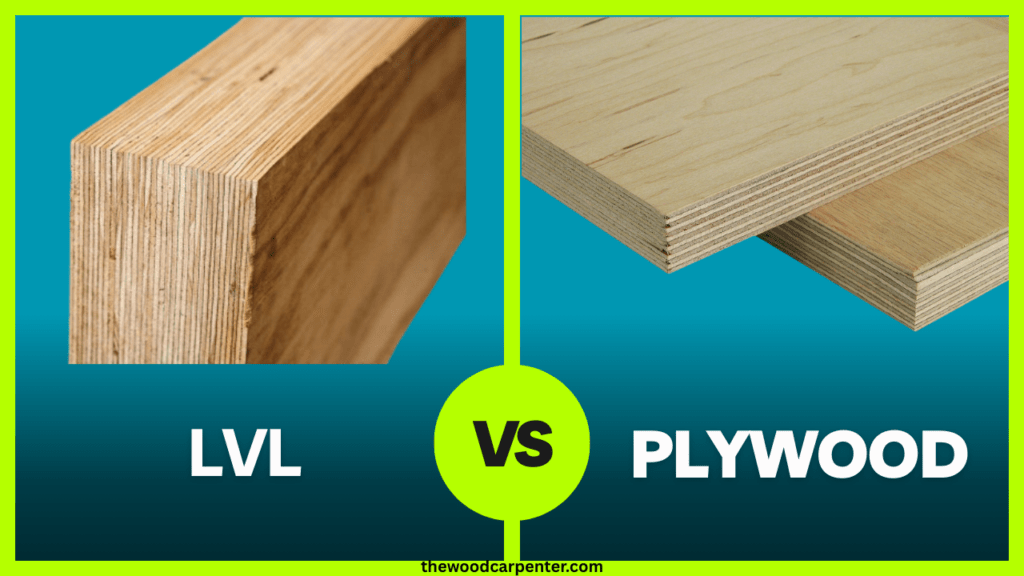

When choosing the right material for your building or woodworking project (or any other DIY endeavor), it is important to understand the difference between Laminated Veneer Lumber (LVL) and plywood.

Each excels at different tasks. In this article, we will outline the differences bewteen LVL and plywood, their pros/cons, the reasons they’re used for certain purposes, cost and related factors such as environmental impact and how to best implement both materials down the line.

What is Laminated Veneer Lumber (LVL)?

Laminated veneer lumber (LVL) is an engineered wood product. It’s constructed by bonding thin sheets of wood together. These are then pressed and heated to form a solid, stable material. LVL is typically used for construction, such as beams, headers and columns, because it is extremely strong.

How is LVL Made?

LVL is constructed from thin wood layers, often coming from fast growing trees such as softwood. The wood is initially peeled into thin sheets and dried. Next, these facings are associated through high-strength adhesive.

The layers are disposed so that grain of the wood in adjacent layers is parallel. This is why LVL is stronger and more stable than solid wood. The adhesive also removes natural defects of wood, so LVL is a more consistent material.

Types of Laminated Veneer Lumber

LVL is available in a range of sizes and grades for various applications. The most common grades include:

Standard LVL: Typically they are used in framing, flooring, and as beams or headers.

High-strength LVL: These are used for applications which will require greater load-bearing capacity, such as in large beams.

Moisture-resistant LVL: It is designed for the environments which are exposed to high humidity.

What all this means is that each type of LVL can be used according to your particular structural requirements, so you can choose which one would suit your project.

What is Plywood ?

Plywood is one type of engineered wood, though it’s made and used in a different way than LVL. It is manufactured by bonding thin layers of wood together. The grain of each layer is orientated in opposite direction to the attached one.

This cross-grain design makes plywood strong and helps prevent warping.

How is Plywood Made ?

Plywood is produced by layering thin wood plies on one another. These layers may be hardwood or softwood. They are bonded together with a powerful glue, with each layer’s grain running in the opposite direction..

This technique, known as cross-lamination, is what makes plywood strong yet flexible and less susceptible to cracking or warping than solid wood.

Types of Plywood

Plywood comes in a variety of types, based on the wood used to produce it and its desired application:

Softwood Plywood: It is usually made of fir, pine or spruce and they are used in structural projects.

Hardwood Plywood: This type is from deciduous trees such as oak and maple, and used for cabinetry and fine woodworking.

Marine Plywood: Exceptionally water resistant; it is utilised for a wet area where you need the added protection, such as boat making.

There are different types of saws that suit different needs such as rough cutting wood or detailed designs of furniture.

Key Differences Between LVL and Plywood

Material Composition

The main difference between LVL and plywood is how the wood layers are arranged. LVL has all its layers facing in the same direction, so it makes it very strong for carrying the heavy loads.

Plywood is made up of layers with the grain going in different directions, so that it will not warp or destabilize, but also does not possess strength in one direction.

Construction and Production Differences

LVL is thicker and has a longer wood layers, so it is great for heavy-duty jobs such as beams and headers. Plywood, which has alternating layers of both grain directions, it is more generally useful in building projects like walls and floors and furniture.

Durability and Strength

LVL is also stronger than plywood and can bear more weight over longer distances. This is what makes it good for all structural applications. Plywood is strong as well, but it flexes more, so it is better suited for the projects that require bending or shaping, such as cabinetry or curved walls.

Applications of Laminated Veneer Lumber (LVL)

Framing and Beams

Laminated Veneer Lumber (LVL) – Used on a large scale in construction, LVL is perfect for framing situations where it’s essential to have long, straight beams or headers. It’s commonly used for walls, ceilings, and roofs.

Furniture Making

It’s also used in furniture construction as well, with a focus on high-strength applications such as tables and shelving units or for designs to build custom furniture. Because of its strength and flexibility, LVL is gaining currency in industrial and residential furniture manufacture.

Also read: OSB vs Plywood: 8 Differences You Need to Watch Out For

CDX vs OSB: Which One Is the Best for Your Next Project?

Applications of Plywood

Wall and Roof Sheathing

Plywood is most commonly used in the construction as a sheathing material for the walls, roofs, and floors. And it’s highly durable, they are easy to work with, and it provides a structural support in these applications.

Decorative Projects

Because of its versatility and aesthetic appeal, plywood is often used in furniture making, cabinetry, and interior decor. Plywood’s smooth surface makes it good and ideal for veneer finishing and painting, allowing for beautiful custom finishes.

Cost Comparison

In terms of pricing, plywood is typically cheaper than LVL. The higher cost is mainly due to LVL’s greater strength and its advanced production process.

However, the cost of LVL may be justified in the situations where higher strength or more precise dimensions are needed, and reducing the amount of material waste or time required for framing and structural work.

Which is Better for Specific Projects ?

Choosing LVL for Structural Projects

For large-scale framing, beams, or any application that demands high strength over long spans, LVL is the best choice for you. It excels in structural integrity and load-bearing capabilities.

Choosing Plywood for Finishing and Design

Plywood is ideal for projects where the appearance matters the most, such as cabinetry, furniture, or decorative wall finishes. It also offers a versatile, cost-effective solution with an easy-to-finish surface.

Frequently Asked Questions (FAQs)

Is LVL stronger than plywood?

Yes, LVL is stronger than plywood because all layers run in the same direction and it’s great for heavy loads.

Can LVL replace plywood?

LVL is an option for accomplishing many of the same things, but it’s not really meant for decorative or lightweight uses.

Which is cheaper, LVL or plywood?

Plywood is generally cheaper, particularly for non-structural applications such as cabinets. But LVL may be cost-effective for applications that require a very strong structure.

Can plywood hold heavy loads?

Though capable of holding weight, plywood is not as strong as LVL. It’s more suitable for decorative or for the flexible projects.

Which is better for the environment?

And because they utilize thin layers of wood from sustainable sources, both of them are eco-friendly. LVL may create less waste.