If you are building a deck, fence, pergola or another garden structure such as a planter box or shed, selecting the right type of wood to use is crucial in preventing an early heartbreak — and wallet-break. A lot of outdoor projects stall out early because ordinary lumber can’t withstand moisture, bugs and soil. That’s where pressure-treated wood comes in handy.

This comprehensive tutorial discusses what pressure treated wood is, how it’s made, compare different types, potential health concerns, applications for pressure treated wood including cost and care considerations – as well as if it can be used in place of other available alternatives. Everything is written in detail so you can decide correctly for your project.

What Is Pressure Treated Wood and How Does It Work?

Pressure treated wood has been infused with chemicals to help protect it from rot, decay and insects!

The treatment is not like painting wood with a protective finish. The timber is loaded in to a large sealed cylinder.

First, a vacuum removes air from the wood cells. Then, preservative chemicals are forced deep into the wood using very high pressure, often up to 150 pounds per square inch. This pressure forces the preservatives deep core of the wood instead of just on the surface.

After treatment, the excess solution drains off and is recycled. The result is wood that is protected from the inside out.

They are typically made of softwoods, such as pine, which absorb preservatives particularly well.

Understanding Modern Pressure Treated Wood Chemicals

The CCA Era and Why It Changed

For decades, chromated copper arsenate (CCA) was the most utilized chemical in pressure treated wood. It worked well, but it had arsenic in it. Because of health worries, CCA was phased out for most residential uses in 2003 and is no longer used for decks, fences or playgrounds.

Older structures built before 2004 may still contain CCA-treated wood. These do not need to be removed, but sealing the surface can reduce exposure.

Modern Copper-Based Treatments

Today’s pressure treated wood mainly uses copper-based preservatives such as:

- Alkaline Copper Quaternary (ACQ)

- Copper Azole (CA)

- Micronized Copper Azole (MCA)

These treatments do not contain arsenic and are approved for residential use. They protect wood from fungi and insects while being significantly safer than older formulas.

The main precaution with modern treated wood is avoiding inhalation of sawdust and prolonged skin contact during construction.

Ground Contact vs Above Ground Pressure Treated Lumber

Not all pressure treated wood is the same. The treatment level depends on where and how the wood will be used.

Above Ground (UC3A / UC3B)

This type is designed for areas that are exposed to weather but do not touch soil. Examples include:

- Deck boards

- Railings

- Fence pickets

It has a lower chemical retention level, making it more affordable and suitable for most visible outdoor surfaces.

Ground Contact (UC4A / UC4B)

Ground contact lumber contains a higher level of preservatives. It is designed for:

- Fence posts buried in soil

- Deck support posts

- Retaining walls

- Foundation sills

Using above-ground lumber in soil can lead to early failure. For any wood touching soil or concrete, always choose ground contact rated lumber.

The rating is shown on the end tag of the board.

Types of Pressure Treated Wood

Besides ground-contact and above-ground ratings, there are a few other variations to understand.

Kiln-Dried After Treatment (KDAT)

Most treated lumber is wet when sold. KDAT lumber is dried after treatment, which reduces warping and shrinking. It costs more but is more stable and easier to work with.

Marine-Rated Lumber

For docks, piers, and seawalls, special marine-rated lumber is required. Standard pressure treated wood is not suitable for saltwater exposure.

Pressure Treated Wood Pros and Cons

Understanding the advantages and disadvantages will help you decide if it is right for your project.

Pros

Pressure treated lumber is very durable. And it can withstand rot, decay and insects for decades.

The investment is relatively inexpensive in the long run. While more expensive than untreated wood, it lasts far longer, which lowers replacement costs.

It’s flexible and can be interlocked together using simple carpentry tools.

Modern treatments are safer than older ones, and approved for residential use.

It holds up well in damp and wet climates where untreated wood would fail quickly.

Cons

Fresh treated wood is most often wet and it may warp or twist as it dries.

The copper can corrode regular steel fasteners and it needs specialized hardware.

It does not have the natural beauty of cedar or redwood.

Chemical exposure during cutting requires basic safety precautions.

How Long Does Pressure Treated Wood Last?

With proper installation and maintenance, pressure treated wood can last:

- 20 to 40 years above ground

- 15 to 25 years in soil contact

- Even longer in well-drained, dry climates

Longevity depends on climate, installation quality, drainage, and correct treatment rating.

Posts installed in gravel-filled holes last longer than posts surrounded by solid concrete that traps water.

Common Uses of Pressure Treated Wood

Pressure treated wood is mainly used for outdoor construction where durability matters.

Decks

Deck framing such as joists, beams, and support posts should always use pressure treated lumber. Deck boards can also be treated wood, offering a durable and budget-friendly surface.

Fences

Fence posts must be ground-contact rated. Rails and pickets can use above-ground lumber.

Landscaping and Retaining Walls

Retaining walls and landscape timbers require ground-contact treatment due to constant soil exposure.

Raised Garden Beds

Modern treated wood is considered safe for raised beds. For extra caution, many people line the inside with plastic before adding soil.

Pergolas, Sheds, and Play Structures

Any outdoor structure exposed to weather benefits from pressure treated framing.

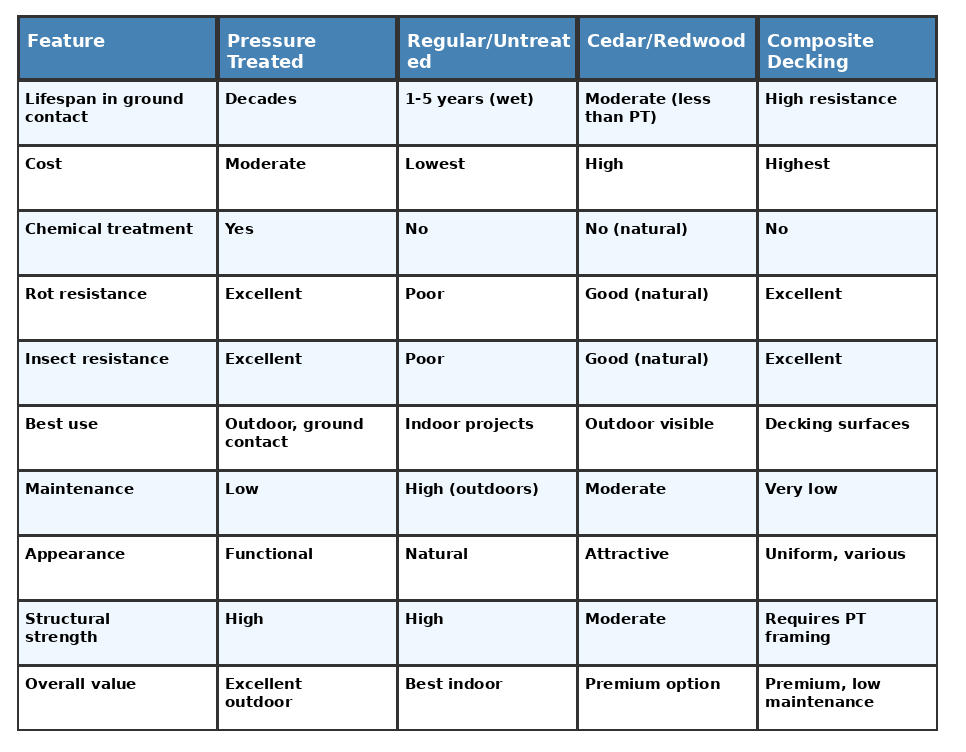

Pressure Treated Wood vs Regular Wood vs Cedar and Alternatives

Is Pressure Treated Wood Safe?

Modern pressure treated wood made with ACQ or CA is considered safe for residential use, including decks and playground structures.

To stay safe:

- Wear gloves when handling

- Wear a dust mask when cutting

- Wash hands after working

- Do not burn scraps

Children playing on treated decks or playsets are not at risk when the wood is properly installed and maintained.

Working with Pressure Treated Wood: Best Practices

Always use hot-dipped galvanized or stainless steel nails, screws, and hardware. Regular steel fasteners will corrode quickly due to the copper content.

Allow wet lumber to dry before staining or sealing. The simple water test works well. If water beads on the surface, the wood is still too wet. If it absorbs, the wood is ready.

Ensure proper drainage around posts. Adding gravel at the base of post holes extends lifespan.

Dispose of scraps properly at approved waste facilities. Never burn treated wood.

How to Stain and Seal Pressure Treated Wood

Allow the wood to dry, then stain or paint it. This can take a few weeks depending on weather.

Use products specifically designed for pressure treated lumber. Apply sealant every couple of years to keep water and sun damage at bay.

Regular care washing with mild soap preserves the look.

Pressure Treated Wood Prices and Buying Tips

Pressure treated lumber generally costs 30 to 50 percent more than untreated wood.

Typical price ranges may look like this:

- 2×4 boards: moderately higher than untreated

- 4×4 posts: higher due to ground-contact treatment

- Deck boards: priced per linear foot

Ground-contact rated lumber costs slightly more than above-ground varieties.

Buying from large home improvement stores or local lumber yards is common. Local yards often offer better bulk pricing and fresher stock for large projects.

Always check the end tag for:

- Treatment rating

- Intended use

- Grade (#1 or #2)

Higher grades have fewer knots and look better for visible surfaces.

Common Mistakes to Avoid

- Using above-ground lumber for buried posts is a common and costly mistake.

- Using standard steel fasteners leads to corrosion and weak joints.

- Installing wood without planning drainage shortens lifespan.

- Painting or staining wood before it dries prevents proper adhesion.

- Burning treated scraps will release harmful fumes so never burn them.

Frequently Asked Questions

Can pressure treated wood be used indoors?

Not unless it is required structurally. For indoor projects, untreated lumber is best.

How can you tell if wood is pressure treated?

It often has a green or brown tint and an end tag showing the treatment rating.

Is pressure treated wood safe for vegetable gardens?

Modern treated wood nowadays is generally considered safe. Lining beds with plastic provides extra protection.

Can pressure treated wood get wet?

Yes. It is designed for moisture exposure, but good drainage still improves lifespan.

How long should pressure treated wood dry before painting?

Usually 4 to 12 weeks, depending on weather. Use the water absorption test to confirm.

What is the difference between #1 and #2 grade?

#1 grade is less defective and looks better. #2 grade is used for structural framing. Both get equal treatment level.

Final Thoughts

The beauty of pressure treated wood products is that they are inexpensive yet have great quality. It is naturally durable long lasting against moisture, insects and decay.

By choosing the appropriate treatment rating, the right fasteners, ensuring adequate drainage & regular maintenance a pressure treated wood project can last decades.

Whether you are building a deck, installing a fence, or creating a garden structure, understanding pressure treated wood helps you build smarter and avoid expensive mistakes.