So, just a couple of months ago, my sister was selecting flooring for her new home and became overwhelmed by the options. Finally, weeks later — after research and contractor conversations — we settled on prefinished hardwood flooring instead. She’s never once regretted it, and today, she’s still a happy woman with that decision.

This guide is essentially everything you need to know about prefinished hardwood flooring if you are considering prefinished hardwood flooring.

What Exactly Is Prefinished Hardwood Flooring?

Prefinished hardwood, as the name suggests, is stained and sealed in the manufacturing plant before it arrives at your home.

Unlike unfinished hardwood, which needs sanding, staining, and sealing after installation, prefinished boards are ready to use as soon as they are installed. You can walk on them immediately.

At the factory, lots of finish coats gets applied in controlled conditions. The majority are UV-cured polyurethane or aluminum oxide finishes. These finishes have long-lasting durability.

You will find 7 to 10 coats on the factory finished floors compared to 2 to 3 on site finished floors. It thus transforms factory finishes into much more durable and longer-lasting products.

Why Homeowners Are Choosing Prefinished Over Unfinished

Over the last decade, more homeowners have chosen prefinished hardwood instead of unfinished wood. Here are the main reasons.

Installation Speed That Actually Matters

In the past, installing traditional hardwood meant a lot of mess and waiting. Sanding created dust everywhere. After that, staining and sealing required several days of drying time. Sometimes homeowners had to move out temporarily.

With prefinished hardwood, installation usually takes only 1 to 3 days, depending on the size of the space. Once the last board is installed, you can move your furniture back right away.

There is no sanding dust, no strong smell, and no long waiting period. This makes life much easier during renovation.

Factory Finish Durability

Factory finishes are cured using UV light, which instantly hardens the surface. This process cannot be done at home.

Because of this, prefinished floors resist scratches, dents, and daily wear better than most site-finished floors.

Many homes with prefinished hardwood installed 15 years ago still look fresh and beautiful. The factory finish simply lasts longer.

Consistent Color Throughout

Staining wood on-site can be tricky. Temperature, humidity, and even the person applying the stain can affect the final color. Sometimes floors look slightly different from room to room.

With prefinished hardwood, every board is treated the same way in a controlled factory environment. The color you choose is the color you get throughout your home. There are no surprises.

Understanding the Different Types and Finishes

Once in a flooring showroom, you may be presented with numerous options. Let’s make it simple.

Wood Species Matter More Than You Think

Different wood species look and perform differently.

1. Oak

The most popular being oak.

The warm tones and prominent grain patterns of red oak make it an excellent choice.

A brighter and more neutral option would be white oak. Both are strong and durable.

2. Maple

Maple has a lighter grain and smooth grind. Very dense, which is great for high-traffic areas, but can be a bit trickier to stain evenly.

3.Hickory

Hickory is one step above in durability and features prominent grain. It gives a rustic look.

4. Brazilian cherry (jatoba)

It features deep character-rich colors that darken all though the years.

5. Walnut

It has the full bodied dark brown tones, but it is less durable than oak, so it has to be treated with more caution.

Finish Types Explained Simply

The factory finishes used on most prefinished hardwood floors are either a polyurethane or aluminum oxide. Some use a combination of both.

Polyurethane finishes provide good protection and are available in matte, satin, or glossy looks. They are inexpensive and function well in most homes.

Aluminum oxide finishes include tiny particles of one of the hardest materials available. The top layer created by this process makes the surface less prone to scratching. This is a great solution for homes with pets or kids. It is a bit more expensive, probably 10–15 % but lasts longer.

Some brands offer oil-based finishes. Unlike many varnishes, which can remain on the surface, these ones soak into the wood. They appear more organic and facilitate better minor repairs, however require greater upkeep on a more frequent basis.

Plank Width and Thickness Considerations

Narrow planks, around 2 to 3 inches wide, give a traditional and classic look.

Wider planks, around 5 to 7 inches, create a modern and open feel. Wider boards also mean fewer seams and quicker installation.

For thickness, solid hardwood is usually ¾ inch thick. Engineered hardwood is usually between 3/8 inch and ½ inch thick.

Thicker floors can be refinished more times. High-quality engineered hardwood with a 4mm or thicker wear layer can be refinished 2 to 3 times.

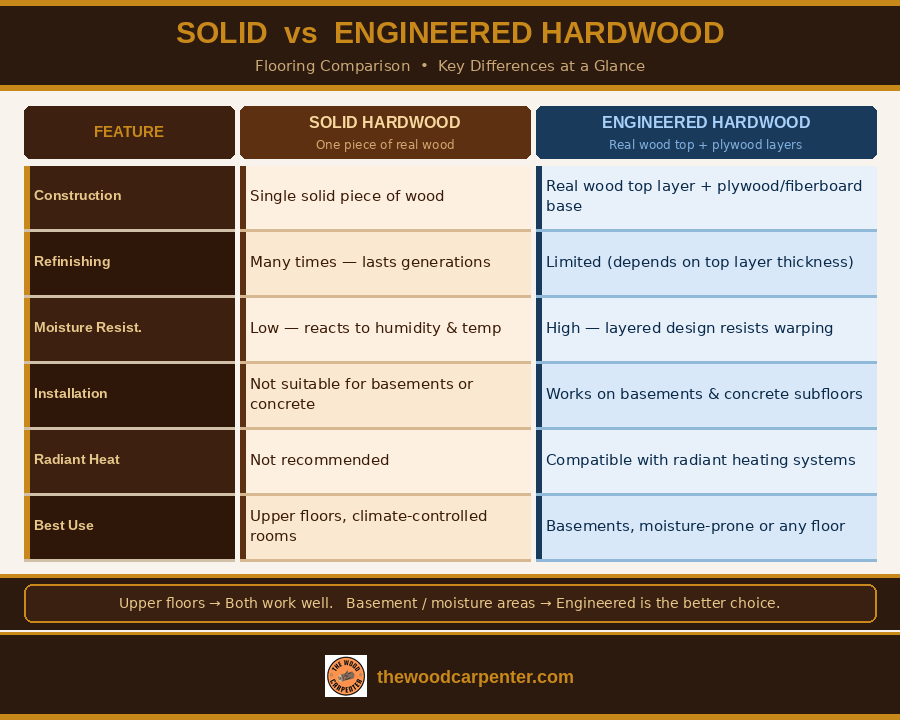

The Engineered vs Solid Debate

What to Expect During Installation

Knowing the process helps you prepare properly.

The first step the installer will do is to check for moisture content and flatness of your subfloor. It also needs to be meet some standard wherein later squeaks or gaps do not become a problem.

Most pre-finished hardwood must stay in your home for 3-7 days prior to installation. This is called acclimation. This will enable the wood to acclimate to the level of moisture in your home.

Solid hardwood is typically nailed or stapled to a wood subfloor.

Engineered hardwood can be nailed, glued, or installed as a floating floor.

Most prefinished boards have micro-beveled edges. These small grooves between boards are normal. They hide small height differences and add character to the floor. Some people like this look, while others prefer a completely smooth finish. Make sure you know your preference before buying.

Maintenance/ Cleaning method that Actually Works

Prefinished hardwood is not completely maintenance-free, but it is easy to care for.

Daily sweep or vacuum with a soft brush attachment. Small dirt particles can scratch the surface over the time.

Use a pH-neutral hardwood cleaner and a slightly damp microfiber mop for cleaning. Do not use too much water. Avoid oil soaps and steam mops.

Put mats at entrances to stop the dust and moisture. Furniture legs can cause a lot of physical damage so it is good to have felt pads on these. Do not walk in with high heels or use any kind of shoe that you think may create a dent.

Most prefinished floors look good for 15 to 25 years before they need refinishing.

Cost Considerations Beyond the Price Tag

Prefinished hardwood usually costs between $6 and $15 per square foot for materials. Installation adds about $3 to $8 per square foot.

So, the total installed cost is around $9 to $23 per square foot.

This is more expensive than laminate or vinyl. However, hardwood can last 50 to 100 years with proper care. It also increases home resale value. Homes with hardwood floors often sell faster and at higher prices.

Vinyl flooring may be cheaper at first but often needs replacement after 10 to 15 years. Over time, hardwood can actually be more cost-effective.

Making Your Final Selection

Always ask for samples before making a final decision. See them in your home, with your own light. Colors appear different under showroom lighting.

Check warranty details carefully. Find at least 25 year finish warranties and structural warranty guarantees on manufacturing defects. Know what will void the warranty (moisture damage and improper cleaning)

Read customer reviews, especially about long-term performance. Look for feedback after 5, 10, or 15 years of use.

Finally, hire an experienced installer. No matter how great your flooring is, it will not perform well with improper installation.

Frequently Asked Questions

How long does it last?

With proper care, prefinished hardwood flooring can last 50–100 years. The factory finish usually lasts 15–25 years before refinishing. Solid wood can be refinished 4–7 times. Engineered wood with a 4mm+ wear layer can be refinished 2–3 times.

Can it be installed over concrete?

Engineered hardwood can be installed over concrete using glue-down or floating methods. Solid hardwood should not go directly over concrete due to moisture problems.

Is it better than site-finished flooring?

Prefinished flooring has a strong factory finish, faster installation, and even color. Site-finished floors look smoother and allow custom stain colors. Most homeowners prefer prefinished for convenience and durability.

How do you clean it?

Sweep or vacuum often. Use a pH-neutral hardwood cleaner with a slightly damp microfiber mop. Avoid steam mops, oil soaps, and excess water. Wipe spills quickly.

Does it scratch easily?

High-quality floors with aluminum oxide finish resist scratches well. Still, all hardwood can wear over time. Use mats and furniture pads for protection.

Can it be refinished?

Yes. Solid hardwood can be refinished several times. Engineered hardwood can also be refinished if the wear layer is thick enough (usually 4mm or more).

What thickness is best?

For solid hardwood, ¾ inch is the standard and best for long-term use. For engineered hardwood, choose at least ½ inch total thickness with a 4mm+ wear layer.

Final Thoughts

Everything from beauty to strength, prefinished hardwood flooring is your best decision for long-term value. It takes little time to install, lasts over a century, and provides warmth to any home. If you pick the proper woods, finish, and installer, then your floors can be beautiful for decades to come.